Fish feed machines are essential equipment for aquaculture operations that produce large volumes of fish feed. These machines are designed to produce high-quality feed pellets with consistent sizes and shapes, which are critical for the health and growth of fish.

The market for fish feed machines is vast, with various options available to meet the needs of different aquaculture operations. In this essay, we will discuss the different types of fish feed machines available in the market.

1. Single Screw Extruder

The single screw extruder is the most commonly used fish feed machine in the aquaculture industry. It is designed to process various types of raw materials into high-quality pellets. This machine has a single screw that rotates within a barrel, where the raw materials are fed. As the screw turns, it pushes the material forward, where it is compressed and cooked by the heat generated from friction. The cooked material is then pushed through a die plate, where it is cut into pellets of a specific size and shape.

2. Twin Screw Extruder

The twin screw extruder is another type of fish feed machine that is commonly used in the industry. It has two screws that rotate in opposite directions within a barrel, which allows for better mixing and cooking of the raw materials. This machine is ideal for processing difficult-to-handle raw materials, such as those with high moisture content or high oil content.

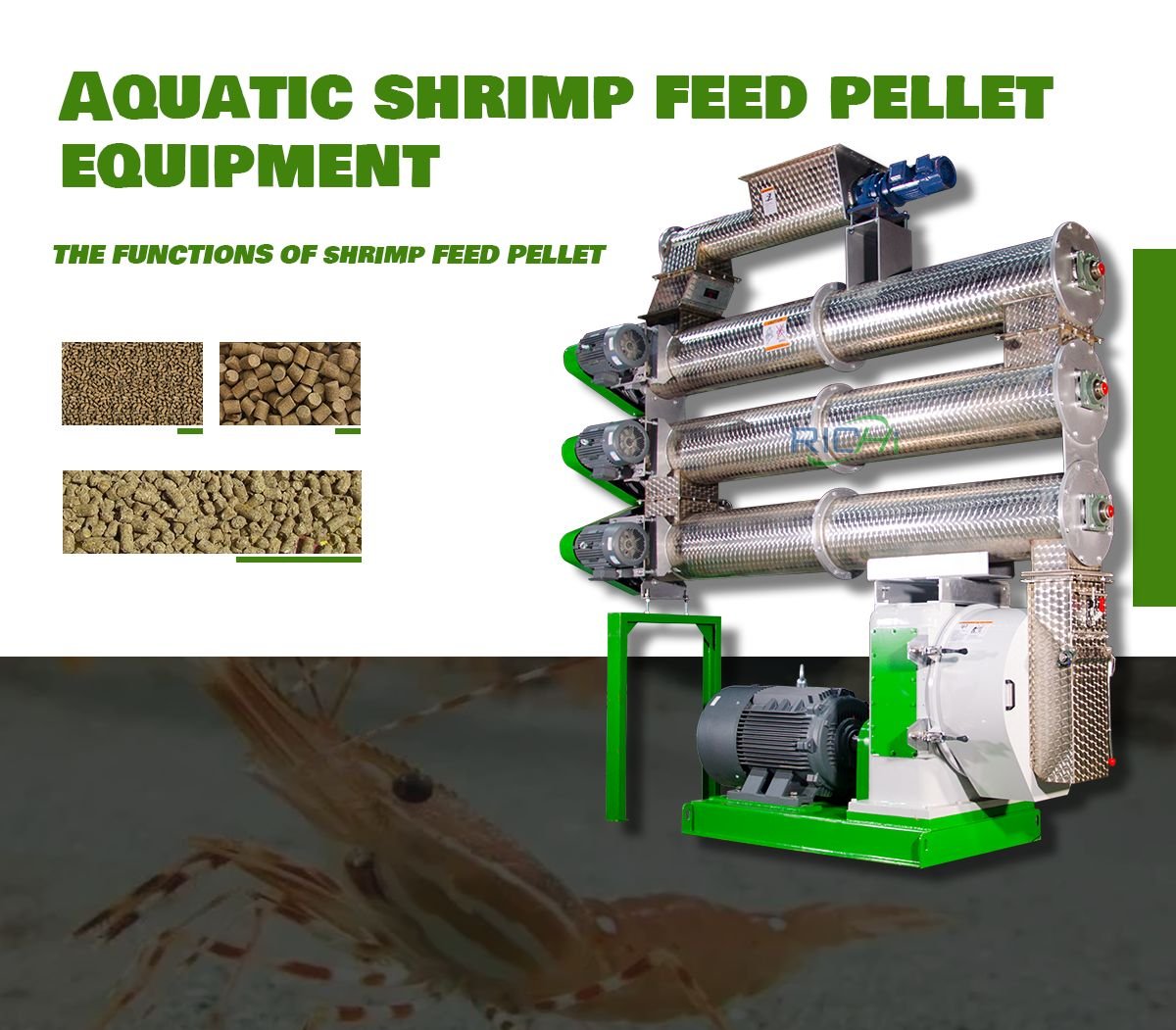

3. Ring Die Pellet Mill

The ring die pellet mill is a popular fish feed machine that is ideal for large-scale aquaculture operations. It uses a rotating die and rollers to compress the raw materials into pellets of a specific size and shape. This machine is capable of producing pellets with high density and high-quality protein content, making it ideal for feeding fish at different stages of development.

4. Flat Die Pellet Mill

The flat die pellet mill is a more affordable option for small-scale aquaculture operations. It uses a flat die and rollers to compress the raw materials into pellets. This machine is relatively simple to operate and maintain, making it ideal for beginners in the aquaculture industry.

5. Wet Type Fish Feed Machine

The wet type fish feed machine is designed to process raw materials that are high in moisture content, such as fresh fish. It uses a conditioner to mix and cook the raw materials, which are then pressed through a die plate to form pellets. This machine is ideal for small-scale aquaculture operations that produce feed for their fish.

6. Dry Type Fish Feed Machine

The dry type fish feed machine is designed to process dry raw materials, such as grains and soybean meal, into pellets. It uses a screw feeder to mix and compress the raw materials, which are then pushed through a die plate to form pellets. This machine is ideal for large-scale aquaculture operations that produce feed for commercial sale.

In conclusion, the aquaculture industry has a wide range of fish feed machines to choose from, depending on the size of the operation, the type of raw materials used, and the desired quality of the feed pellets. Single screw extruders and twin screw extruders are commonly used in the industry, while ring die pellet mills and flat die pellet mills are ideal for large-scale and small-scale operations, respectively.

Wet type fish feed machines are designed for processing raw materials with high moisture content, while dry type fish feed machines are ideal for processing dry raw materials. Understanding the different types of fish feed machines available in the market can help aquaculture operators choose the best machine for their specific needs.