Livestock feed pellet machines are specialized equipment designed to convert raw materials and animal feed ingredients into compact, uniformly-sized pellets. These machines play a pivotal role in the animal feed industry by ensuring that livestock, including pigs, sheep, and cattle, receive nutritionally balanced and high-quality feed. The primary purpose of these machines is to enhance the digestibility and absorption of feed nutrients by compressing feed into dense pellets, which helps in reducing wastage and optimizing feed efficiency.

There are various types of livestock feed pellet machines tailored for different animal species. For instance, machines designed for pig feed cater to the specific dietary needs of swine by creating feed pellets that are easily digestible and fortified with essential nutrients. Similarly, sheep feed pellet machines produce pellets that are rich in fiber, vitamins, and minerals, aligning with the dietary requirements of ovine animals. Cattle feed pellet machines, on the other hand, are engineered to produce high-protein and fiber-rich pellets that support the growth and health of bovines. Each type of pellet machine is calibrated to ensure that the feed is palatable and nutritionally adequate for the targeted livestock.

Moreover, these machines contribute significantly to the efficiency of feed production and livestock farming operations. By using livestock feed pellet machines, farmers can streamline the feed preparation process, reduce storage space, and maintain the consistency of feed quality. This not only promotes better animal health and growth but also facilitates more efficient farm management practices. Overall, livestock feed pellet machines are indispensable tools in modern animal husbandry, underscoring their importance in ensuring that livestock receives a well-balanced diet, leading to improved productivity and health outcomes.

Market Analysis and Profitability of Livestock Feed Pellet Machines

The market for livestock feed pellet machines has been experiencing a significant upward trajectory, driven by the rising global demand for efficient and high-quality animal feed. According to recent data, the market value is projected to grow at a compound annual growth rate (CAGR) of 5.5% over the next five years. This growth is predominantly fueled by the increasing awareness among livestock farmers about the benefits these machines offer, including better feed conversion rates and reduced feed wastage. The versatility and efficiency of livestock feed pellet machines make them an indispensable asset within the livestock industry.

In terms of market size, the Asia-Pacific region holds the largest share, followed closely by North America and Europe. This can be attributed to the substantial livestock populations in these regions and stringent feed quality regulations that necessitate the use of advanced feed processing equipment. Farmers are increasingly adopting these machines to streamline operations and enhance productivity, thereby driving market demand. Emerging markets in Africa and Latin America are also showing promising growth potential, with investments being funneled into modernizing agricultural practices.

From a profitability standpoint, investing in a livestock feed pellet machine offers several economic benefits. By enabling on-site pellet production, farmers can significantly cut down on feed costs, which constitute a major portion of livestock rearing expenses. Additionally, the improved nutritional content and digestibility of pellets contribute to better livestock health and growth rates, resulting in higher yields and better market prices for livestock products. The payback period for these machines is typically short, making them a financially sound investment for both small-scale and large-scale operators.

Beyond economic advantages, livestock feed pellet machines play a critical role in promoting sustainability within the industry. By utilizing agricultural by-products and waste materials to produce feed pellets, these machines help in reducing environmental footprint and promoting resource efficiency. The widespread use of these machines across the industry underscores their importance in enhancing overall livestock productivity and profitability.

Technical Classification, Working Principles, and Process Flow

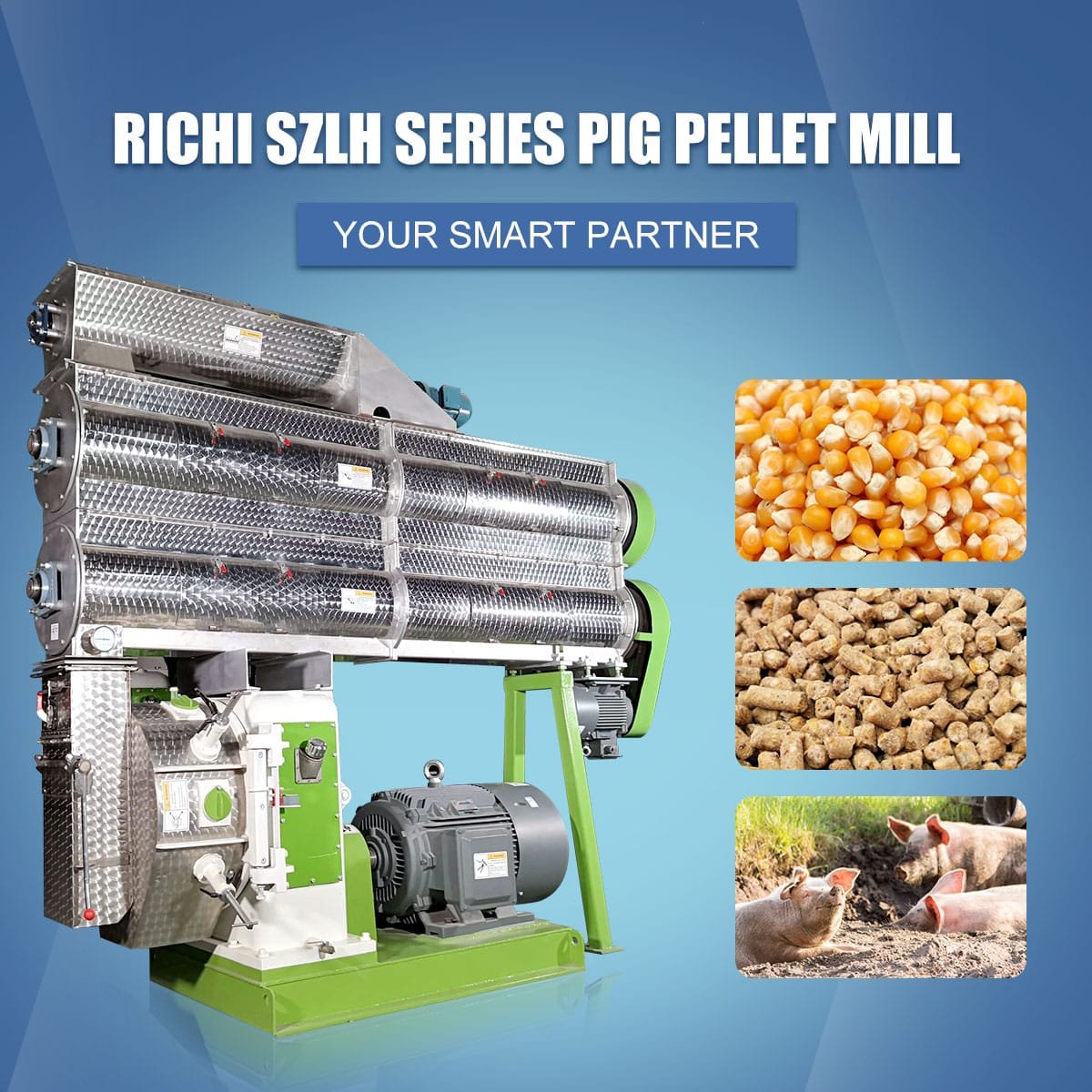

Understanding the technical intricacies of livestock feed pellet machines is paramount to selecting the right equipment for your agricultural needs. These machines generally fall into two primary categories: ring mold pellet machines and flat mold pellet machines. Each type exhibits distinct mechanical and operational characteristics, impacting their suitability for different applications.

Ring mold pellet machines feature a rotating ring die, through which feed material is compressed by rollers. This configuration allows for higher production capacities and more consistent pellet quality, making them ideal for large-scale operations. On the other hand, flat mold pellet machines utilize a stationary die with compressing rollers that press material vertically. This design is typically more straightforward and is often suitable for smaller, less demanding applications.

Working principles for these machines can be distilled into several stages. Initially, raw materials are fed into the feeding system, where they are pre-conditioned through mixing and moisture adjustment. This ensures uniform consistency before entering the pelletizing chamber. Within the chamber, the feedstock is subjected to mechanical pressure, transforming the material into compact, uniform pellets. Finally, the pellets are cooled and can be screened to remove fines, enhancing their usability.

Manufacturers like Richi Machinery excel in customizing these machines to meet specific customer requirements. Whether operating on a small or large scale, customization options can include tailored die configurations, roller designs, and even automated control systems to optimize the pelletizing process. This bespoke approach ensures that the livestock feed pellet machine not only meets production requirements but also aligns with operational and economic objectives.

Thus, investing in a customized livestock feed pellet machine elevates efficiency, product quality, and the overall production workflow, making it an invaluable asset to any livestock feed production endeavor.

Case Studies and Solutions for Common Challenges

When working with livestock feed pellet machines, several challenges can arise at various stages of project implementation. To illustrate, consider a project involving a livestock feed pellet machine with a capacity of 2 tons per hour. During the program design phase, the client needed a compact setup due to limited space. Our engineers resolved this by customizing a modular, vertically integrated design that maximized efficiency while minimizing the footprint.

Another case involved an 80-ton per hour setup. The primary challenge was the seamless integration of the new machinery into an existing production line without disrupting operations. The solution lay in meticulous planning of the site setup, rigorous pre-testing of equipment functionality, and ensuring modular compatibility. By employing a phased installation approach, the production line was upgraded with minimal downtime.

Moreover, a common issue encountered during installation is the alignment and calibration of the livestock feed pellet machine. For a project with a capacity of 50 tons per hour, our technicians used precision instruments for alignment and conducted multiple test runs to optimize calibration. This not only ensured smooth operation but also reduced wear and tear on the machinery.

Effective after-sales service is another cornerstone in addressing common challenges. For instance, a customer using a 20-ton per hour pellet machine experienced unexpected downtimes due to software glitches. Richi Machinery’s swift response included remote troubleshooting and on-site technical support, drastically reducing operational disruptions and maintaining productivity.

Choosing Richi Machinery for custom pellet production lines means benefiting from deep-rooted expertise in program design, comprehensive site setup, robust equipment functionality, seamless installation, and reliable after-sales service. Our ability to navigate and resolve these challenges positions us as a trusted partner in the field of livestock feed pellet production.

Related case: https://www.richimanufacture.com/animal-feed-production-line-in-saudi-arabia/

Conclusion and Frequently Asked Questions

In conclusion, the livestock feed pellet machine stands as an indispensable asset for modern farming operations. The adoption of these machines has significantly revolutionized the livestock feed industry by enhancing feed quality, optimizing efficiency, and streamlining production processes. By compressing various feed materials into uniformly dense pellets, these machines ensure balanced nutritional content, which in turn contributes to the overall health and growth of livestock.

Furthermore, the operational efficiency of livestock feed pellet machines cannot be overstated. Most machines are designed to meet varying production demands, all while maintaining energy efficiency and reducing wastage. Routine maintenance, which often involves cleaning and lubrication, is essential to prolong the lifespan of the machine and maintain its performance. While sophisticated models may require professional servicing, many issues can be addressed through regular inspections and adherence to manufacturer instructions.

Below, we address some frequently asked questions to further assist in understanding and maximizing the benefits of livestock feed pellet machines:

Frequently Asked Questions

1. How does the livestock feed pellet machine improve feed utilization?

By compressing feed materials into small, dense pellets, the machine ensures that nutrients are evenly distributed within each pellet. This uniformity helps livestock to consume feed more efficiently, thereby reducing feed wastage and enhancing nutritional intake.

2. What are the main maintenance requirements for these machines?

Regular maintenance includes cleaning the machine to remove residual feed, lubricating moving parts to reduce friction, and checking for any wear and tear on the components. Following the manufacturer’s maintenance guidelines can significantly extend the machine’s operational life.

3. Can the livestock feed pellet machine process different types of feed materials?

Yes, these machines are highly versatile and can process various types of feed materials, including grains, seeds, and forage. The adaptability of the machine allows farmers to customize feed pellets according to the specific dietary needs of their livestock.

Overall, understanding the operational intricacies and maintenance requirements of a livestock feed pellet machine will empower potential buyers to make well-informed decisions. With the right approach, these machines can be a pivotal element in achieving efficient, sustainable, and high-quality livestock farming.