The aquaculture industry has experienced significant growth in recent years, with both shrimp and fish farming playing vital roles in satisfying global seafood demand. Consequently, the production of high-quality aquatic feeds has become increasingly important. A common question among aquaculture feed producers is whether shrimp feed pellet machines can also process fish feed. The answer is affirmative, but certain important considerations and adaptations are necessary.

Similarities and Differences Between Shrimp and Fish Feed

Before examining the capabilities of shrimp feed pellet mill machines, it’s essential to understand the similarities and differences between shrimp and fish feed:

Similarities:

- Both require high-quality protein sources.

- Both need a balance of essential nutrients.

- Water stability is important for both types of feed.

Differences:

- Fish feed often requires higher fat content.

- Shrimp feed typically has a higher moisture content.

- Pellet size and density requirements can vary significantly.

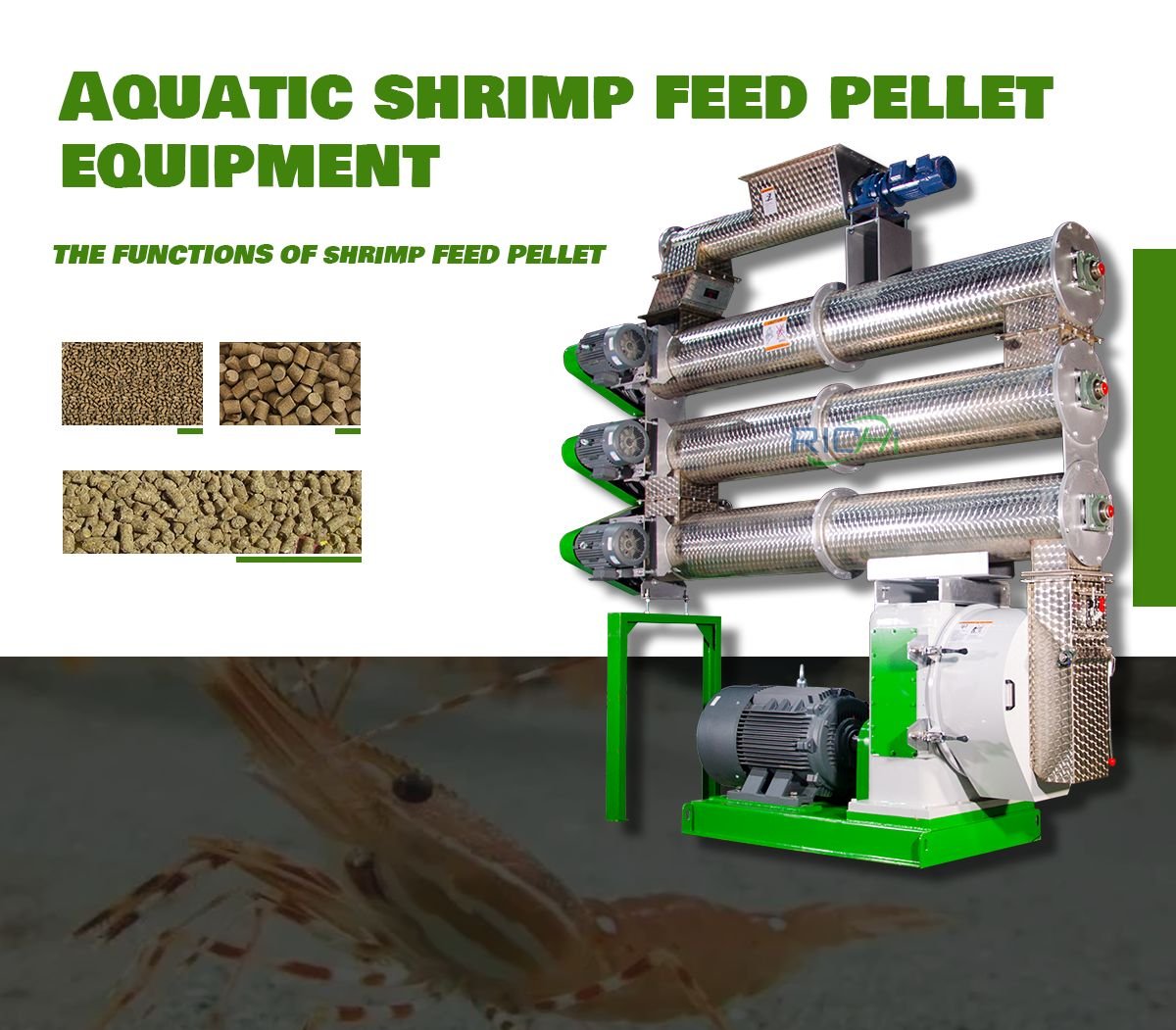

Capabilities of Shrimp Feed Pellet Machines

Modern shrimp feed pellet machines are versatile and can be adapted to produce various types of aquatic feeds, including fish feed. Key features that make these machines suitable for fish feed production include:

- Adjustable Pellet Size: Shrimp feed pellet machines typically produce pellets ranging from 0.8mm to 3mm in diameter, which is suitable for many fish species, especially in their juvenile stages.

- Temperature Control: These machines offer precise temperature control during the extrusion process, which is crucial for maintaining the nutritional integrity of ingredients in both shrimp and fish feeds.

- Flexibility in Ingredient Processing: Shrimp feed pellet machines can handle a wide range of ingredients commonly used in fish feed formulations, including fishmeal, plant proteins, and various additives.

- Moisture Control: Although shrimp feed typically requires higher moisture content, many shrimp feed pellet machines can be adjusted to manage the lower moisture levels often found in fish feed formulations.

Adaptations Needed for Fish Feed Processing

While shrimp feed pellet machines can process fish feed, some adaptations may be necessary to optimize the process:

- Die Configuration: Fish feed often requires different pellet shapes and sizes compared to shrimp feed. The machine may need to be equipped with specialized dies for fish feed production.

- Extruder Barrel Configuration: The extruder barrel may need reconfiguration to accommodate the different cooking requirements of fish feed ingredients.

- Fat Injection System: Many fish species require higher fat content in their diet. A fat injection system may need to be added or modified to incorporate higher levels of oils into the feed.

- Cooling System: Fish feed pellets may require different cooling processes compared to shrimp feed, necessitating adjustments or upgrades to the cooling system.

- Floating Feed Production: For species that require floating feed, additional equipment or modifications may be necessary to produce pellets with the right density and expansion characteristics.

Benefits of Using Shrimp Feed Pellet Machines for Fish Feed

Utilizing shrimp feed pellet machines for fish feed production offers several advantages:

- Versatility: The ability to produce both shrimp and fish feed with the same equipment provides flexibility for feed manufacturers.

- Cost-Effectiveness: Using one machine for multiple types of feed can be more economical than investing in separate equipment for each feed type.

- Space Efficiency: For facilities with limited space, having a single machine capable of producing various feeds is advantageous.

- Consistent Quality: The precise control mechanisms in shrimp feed pellet machines can ensure consistent quality in fish feed production.

- Scalability: Many shrimp feed pellet machines are designed for high-capacity production, which can benefit large-scale fish feed manufacturing.

Challenges and Considerations

While shrimp feed pellet machines can be adapted for fish feed production, there are some challenges to consider:

- Formulation Adjustments: Fish feed formulations may need to be modified to work optimally with the shrimp feed pellet machine.

- Production Efficiency: The machine may not be as efficient in producing fish feed as it is with shrimp feed, potentially leading to lower production rates.

- Pellet Characteristics: Achieving the desired pellet characteristics (e.g., floating vs. sinking, oil absorption capacity) may require significant adjustments and testing.

- Cleaning and Changeover: Thorough cleaning may be necessary when switching between shrimp and fish feed production to prevent cross-contamination.

- Regulatory Compliance: Ensure that the adapted machine meets all regulatory requirements for fish feed production.

Case Studies and Industry Examples

Several feed manufacturers have successfully adapted shrimp feed pellet machines for fish feed production:

- A feed mill in Southeast Asia reported using a single extruder to produce both shrimp and tilapia feed, adjusting the formulation and processing parameters for each.

- An aquafeed company in South America modified its shrimp feed pellet machine to produce feed for local fish species, resulting in a 30% increase in overall equipment utilization.

- A research facility in Europe used an adapted shrimp feed pellet machine to conduct comparative studies on nutrient digestibility between shrimp and fish feeds.

Future Trends

As the aquaculture industry continues to evolve, we can expect further advancements in feed production technology:

- Hybrid Machines: Development of machines specifically designed for dual-purpose production of both shrimp and fish feeds.

- Advanced Control Systems: Integration of AI and machine learning for automatic optimization of processing parameters when switching between feed types.

- Sustainable Ingredient Processing: Machines capable of efficiently processing a wider range of sustainable and alternative ingredients for both shrimp and fish feeds. (Related post:fish feed pellet machine price )

Conclusion

Shrimp feed pellet machines can indeed produce fish feed, providing a versatile solution for aquafeed manufacturers. These machines offer the flexibility to produce different types of aquatic feeds, potentially reducing equipment costs and increasing production efficiency. However, successful adaptation requires careful consideration of the differences between shrimp and fish feed requirements, as well as potential modifications to the machine and production process.

For feed manufacturers considering using shrimp feed pellet machines for fish feed production, thorough testing and optimization are crucial. This ensures that the produced fish feed meets the nutritional requirements of the target species and complies with industry standards and regulations.

As aquaculture plays an increasingly important role in global food security, the ability to efficiently produce high-quality feeds for various aquatic species becomes ever more critical. The adaptability of shrimp feed pellet machines to process fish feed represents a promising development in this direction, offering potential benefits in production flexibility, cost-effectiveness, and resource utilization in the aquafeed industry.