The complete feed processing machinery includes raw material storage, cleaning machine, crusher, mixer, feed pellet machine, cooler, classifier, automatic packing machine, conveyor and electric control system. The above process is only for reference. We can customize solutions according to your needs.

Firstly putting the raw material of specific proportion into the screw conveyor. Then the raw material would be crushed into powder by the hammer mill. After that, the powder would be completely mixed in the animal feed mixer.

After mixing, the powder is conveyed into the conditioner by the variable frequency feeder. And in the conditioner, the powder is fused with steam. After reaching a certain temperature and moisture, the powder enters the ring die feed pellet machine. Then the powder is strongly squeezed by the ring die and the pressure roller to form granules. Under the strong compression of the ring die and the pressure roller, the granules are formed and then cut into the desired length by the cutter.

Then, the conveyor puts the pellets into the cone bucket. The pellets passes through the cone bucket and are discharged into the cooler. Then the pellets get through the vibrating screener. After sieving, the pellets can be packed.

As we all know, animals mainly refers to the domesticated animals, such as chicken, duck, goose, cattle, horse, etc. When raising animals, it is usually necessary to feed them, so as to improve their nutritional intake, promote their normal growth and facilitate higher economic benefits for people. Existing animal feed pellets is usually packaged directly after processing and production without pelletizing the feed, which makes it difficult to store and transport.

The feed pellets can facilitate the storage and transportation of feed by pelletizing it. It avoids wasteful flow of bulk feed through gaps in the packaging equipment, and facilitates the consumption of pelleted feed, improving practicality and reliability.

What is a feed pellet machine? Making mixed powdery feed into granules can improve the nutrition and edible quality of feed to varying degrees. Granulation is not only suitable for livestock and poultry feed, but also for aquatic products and special feed. Due to the variety and composition of feed raw materials and the scale of finished products, there are different requirements for the performance and structural parameters of feed granulation equipment.

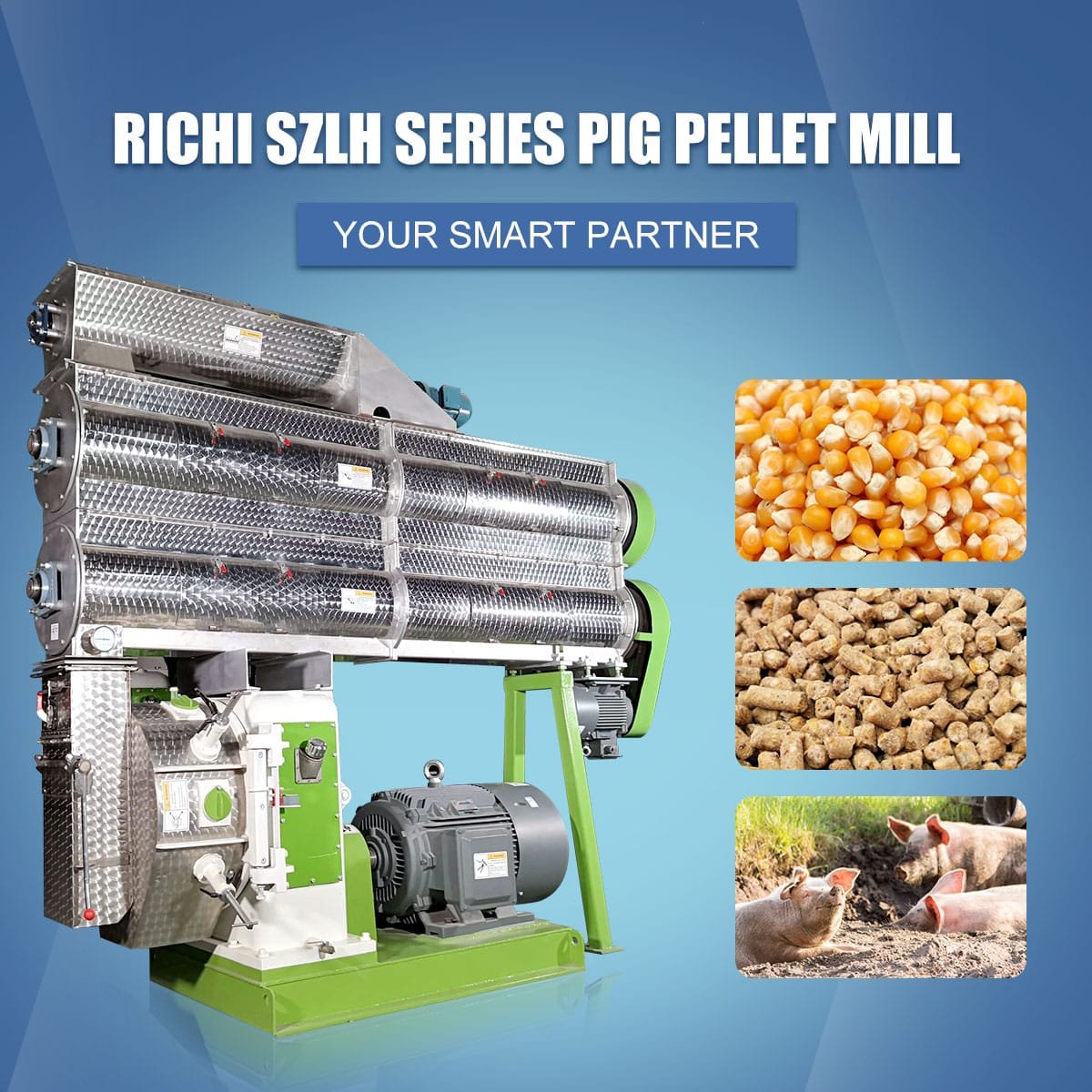

The feed pellet machine used in feed factories and large and medium-sized farms is mainly ring die granulator. The evaluation standard of type selection is mainly based on the rationality of structural design, convenience of operation, structural parameters, processing method, manufacturing level, etc.

RICHI feed pellet machine is suitable for producing all kinds of animal feed pellets, such as chicken, broiler, hen, turkey, duck, goose, pigeon, etc. The equipment is mainly available for the raw materials including wheat bran, rice bran, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc. The finished pellet size ranges from 1.5mm to 12mm.

When raising animals, it is usually necessary to feed them, so as to promote their normal growth and facilitate higher economic benefits for people. Existing animal feed is usually packaged directly after processing and production without pelletizing the feed, which makes it difficult to store and transport.

RICHI feed pellet machine can produce feed pellets that are suitable for all kinds of animals. The advantages of the feed pellets are as following:

- Increasing the feed intake of poultry and animals and reduce feed waste.

- When changing the feed formula, it can be more easily accepted by animals.

- Improving the conversion rate of feed digestion.

- Preventing picky feeding of animals to ensure good nutritional feed formula.

- High temperature and steam sterilization can eliminate harmful microorganism in animal feed.

- High quality animal feed pellets can withstand repeated treatment and remain intact during bagging, transportation, storage and delivery of the feeding line.

Feed pellet machine is the most important poultry feed manufacturing machine for animal feed factories and poultry farms to produce granular feed. Animal pellet feed is a strip feed made of powdered feed extruded by feed pellet machine. It is a popular feed form today. In recent years, with the rapid development of feed industry, animals pellet feed has been gradually accepted by the majority of farmers. Therefore, for animal feed plants or animal farms, the establishment or the purchase of feed processing machinery are very promising.