Understanding Biomass Pellet Mills

Biomass pellet mills are pivotal machines in the renewable energy landscape, facilitating the conversion of various biomass materials into biofuel pellets. These mills are essential for processing organic materials such as wood, agricultural residues, and other biodegradable substances into compact pellets that serve as renewable energy sources. The transformation process involves compressing the biomass under high pressure, binding the material without the need for additional adhesives.

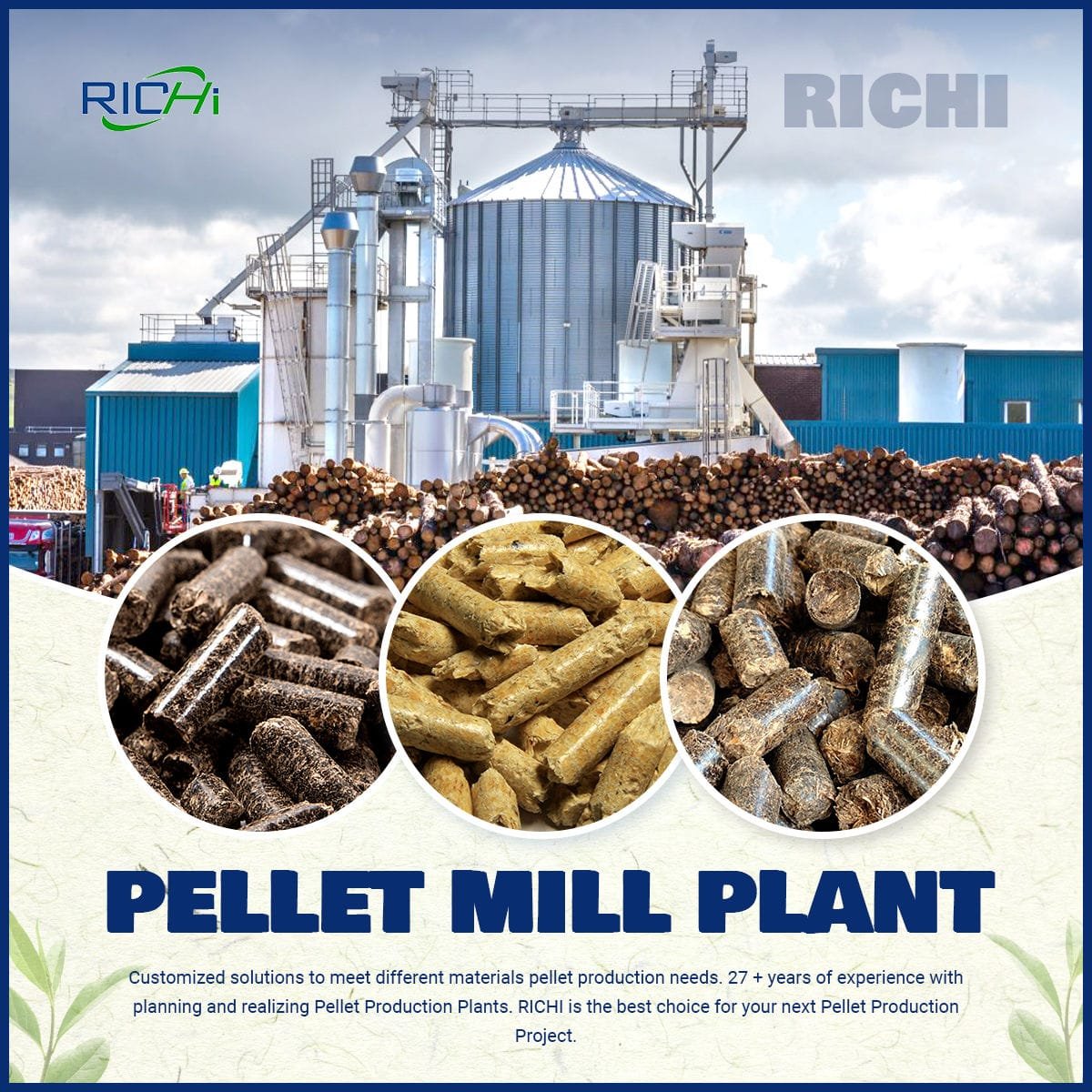

A differentiating feature of biomass pellet mills lies in their versatility, allowing a wide array of materials to be processed efficiently. Wood chips, sawdust, straw, rice husks, and even certain grasses can be transformed into uniform, energy-dense pellets. The key attributes of these mills include a robust design to withstand continuous operation, energy efficiency, and the ability to handle varying moisture contents of the input materials. Highly engineered roller and die frameworks ensure that the pellets produced are of consistent quality and density.

From an industrial perspective, biomass pellet mills play a significant role in advancing sustainability efforts. By converting waste materials into valuable energy resources, they reduce landfill usage, lower greenhouse gas emissions, and promote a circular economy. These mills are integrated into biomass plants and energy production facilities, contributing substantially to energy diversification and reduction of dependence on fossil fuels.

When choosing a biomass pellet mill, several parameters should be meticulously evaluated. Capacity is a primary consideration – it determines how much material the mill can process in a given timeframe, usually expressed in tons per hour. Power consumption is another crucial factor, as it impacts the operational cost and energy efficiency of the mill. Durable components, including the die and rollers, are vital for ensuring longevity and consistent performance under rigorous conditions. Furthermore, ease of maintenance and the availability of replacement parts can significantly affect the operational downtime and overall efficiency of the mill.

In practice, a well-chosen biomass pellet mill becomes a cornerstone of sustainable energy initiatives, enabling the large-scale production of biofuel and supporting the growth of green energy solutions globally.

Detailed Parameters of RICHI Biomass Pellet Mill

The RICHI biomass pellet mill stands out in the market due to its high-quality materials, innovative technology, and robust performance capabilities. The machines are crafted from premium-grade stainless steel, ensuring durability and longevity even under intense workloads. This high material quality directly translates to lower maintenance costs and extended periods of operational reliability.

When it comes to production capacity, RICHI biomass pellet mills showcase versatility, catering to various scales of operation. For instance, the RICHI MZLH Series offers models with output capacities ranging from 1 to 20 tons per hour, making them suitable for both small-scale producers and large industrial operations. This adaptability is vital for businesses aiming to scale their operations over time without necessitating a complete overhaul of their machinery.

Energy efficiency is another critical parameter where RICHI excels. The advanced pellet mills are designed with energy-saving mechanisms, reducing power consumption significantly. This attribute not only lowers operational costs but also aligns with sustainable practices, a growing concern in today’s production environments. The inclusion of high-efficiency motors, with power outputs from 55kW to 320kW depending on the model, ensures optimal performance with minimal energy wastage.

Technological innovations embedded in RICHI biomass pellet mills include automated controls and safety enhancements. Automated control systems, often equipped with sophisticated PLC (Programmable Logic Controller) interfaces, allow for streamlined operation and monitoring. This automation ensures precision in processing parameters, thereby enhancing the overall quality of the pellets produced. Safety features such as emergency stop mechanisms and overload protection further ensure a secure operation environment, minimizing risks associated with high-production machinery.

Specific model features, such as adjustable pellet sizes ranging from 4mm to 12mm, cater to diverse applications, from domestic heating solutions to industrial fuel requirements. These detailed parameters collectively offer end-users numerous advantages. Enhanced efficiency, superior pellet quality, and cost-effectiveness are prominent benefits, making RICHI biomass pellet mills a preferred choice for those committed to excellence in biomass production.

Key Considerations When Choosing a Biomass Pellet Mill Manufacturer

When selecting a biomass pellet mill manufacturer, several critical factors must be taken into account to ensure a successful and sustainable investment. The reputation of the manufacturer is paramount; established companies with a proven track record generally indicate reliability and quality. Researching the manufacturer’s history and client feedback can provide valuable insights into their market standing and reliability.

Product quality is another essential factor. Assess the materials used in manufacturing the mills, the sophistication of the technology involved, and the overall durability of the equipment. High-quality biomass pellet mills not only perform better but also have a longer lifespan, leading to lower replacement costs in the long run.

Customer service is crucial. A manufacturer who offers excellent pre-sales guidance and support aids in making informed decisions tailored to specific needs. Equally important is the availability of after-sales support, including technical assistance, troubleshooting, and maintenance services. Comprehensive after-sales support can significantly reduce downtime and operational issues, ensuring smoother processing.

Certifications and warranties also hold significant value. Certifications from recognized bodies often reflect adherence to industry standards and regulatory compliance, which is crucial for both safety and performance. A robust warranty signifies the manufacturer’s confidence in their product and provides the buyer with assurances on product reliability and service commitments.

Experience in the field cannot be overlooked. Manufacturers with extensive industry experience are likely to have developed advanced technologies and superior products. Their long-term presence in the market also implies resilience and adaptability to changing demands and innovations. Moreover, verifying the availability of spare parts is essential to ensure long-term operability and efficiency of the biomass pellet mill.

To assess credibility, potential buyers should meticulously evaluate customer reviews and solicit testimonials. Visiting manufacturing facilities can offer a firsthand look at the production processes, quality control measures, and operational standards. Lastly, seeking professional advice from industry experts can provide nuanced perspectives and recommendations, guiding you toward a well-informed purchasing decision.

Top Three Pellet Machine Manufacturers: A Comparison

When it comes to selecting the right biomass pellet mill, understanding the leading manufacturers in the industry is crucial. Among these, three companies stand out: Andritz, CPM, and RICHI Machinery. This section will provide a comparative analysis of these manufacturers, with a particular focus on why RICHI Machinery is distinguished in the market.

Andritz is recognized for its extensive portfolio and global presence, offering a wide range of biomass pellet mills and related solutions. They are known for their robust engineering and the ability to provide comprehensive processing systems. However, their solutions often come at a premium cost, which may not be feasible for all businesses, especially smaller enterprises.

CPM (California Pellet Mill) is another key player, renowned for its durable and high-quality machinery. With a long-standing history in the pellet mill industry, CPM has built a strong reputation for reliable equipment. Yet, similar to Andritz, the high cost associated with CPM equipment can be a limiting factor for many buyers.

RICHI Machinery, ranked third in renown but arguably first in delivering value, distinguishes itself with several competitive advantages. Based in Henan, China, RICHI Machinery has emerged as the most professional pellet mill manufacturer in the region. Its recognition as the largest manufacturer in Henan is a testament to its operational scale and capability.

RICHI offers a comprehensive range of pellet mills tailored to different needs, from small-scale operations to larger industrial applications. This versatility, coupled with their turnkey project services, positions RICHI as an all-encompassing provider. Their machinery boasts innovative features that enhance efficiency and durability, ensuring high performance even under strenuous conditions.

One of RICHI’s standout qualities is its commitment to innovation and technological advancement. They continuously invest in research and development to improve their biomass pellet mill offerings. Additionally, their products are competitively priced, providing excellent value for money without compromising on quality. This cost-effectiveness makes RICHI Machinery a preferred choice for various market segments, from startups to established enterprises.

In comparison to Andritz and CPM, RICHI’s balance of affordability, innovation, and comprehensive customer service gives it an edge. While Andritz and CPM offer highly reliable products, RICHI combines reliability with cost-efficiency and versatility, making it a superior option for businesses looking to maximize their investment in pellet mill technology.

Conclusion: Making an Informed Decision

Choosing the right biomass wood pellet mill is a critical decision that requires careful consideration of various factors. As discussed in the preceding sections, understanding the technical specifications, the types of raw materials, and the desired production capacity are pivotal in making an informed decision. Equally important is selecting a reputable manufacturer with proven expertise and a strong market presence.

RICHI Machinery stands out in the industry due to its unparalleled expertise and market position. Their comprehensive range of biomass pellet mills, combined with a commitment to quality and innovation, makes them a reliable choice for any prospective buyer. The company’s dedication to customer satisfaction and long-term support differentiates it from competitors, ensuring that clients can rely on their products for efficient and sustainable biomass production.

A high-quality biomass pellet mill from a trusted manufacturer like RICHI offers numerous long-term benefits. These include enhanced operational efficiency, reduced maintenance costs, and improved product quality, which collectively contribute to a more sustainable and profitable business model. By carefully evaluating their specific requirements and utilizing the information provided in this guide, buyers can make a well-informed purchasing decision that aligns with their operational needs and strategic goals.

In conclusion, investing in a biomass pellet mill is a significant commitment, and selecting the right equipment is crucial for achieving optimal results. By prioritizing high-quality machinery from established manufacturers like RICHI, businesses can ensure they are making a sound investment that will yield substantial returns in the long run.