Recently, I have summarized the questions of many friends and found that many people are asking about the formula of pellet feed, which is made by poultry feed pellet making machine. In fact, the raw materials and livestock and poultry used by each customer are different and cannot be generalized. Feed pellet machine formula should follow 3 principles, here are some suggestions for reference:

(1) For the customers who breed by themselves, what materials are there now?

That is to say, if you breed by yourself, you can use whatever material you used before and what material you use now. For example, you feed pigs with corn, bran, and sweet potato seedlings, then crush these three, and then use a feed pellet machine to make pellets.

(2) Pellets can be mixed with a variety of raw materials, not just one material.

In the cognition of many friends, only one material is used when using a poultry feed pellet making machine to press pellets. For example, I only use corn stover. In fact, this is not the case. You can pulverize various materials, then mix and stir, and then make granules. Pellets have always been known for their nutritious, sweet taste, so their nutrient richness is not only reflected in one aspect.

So you don’t have to think that the poultry feed pellet making machine is an artifact that is out of reach.

(3) When the pellet feed is configured, the ratio of roughage is generally 6:4.

When using a poultry feed pellet making machine to press pellets, if you have roughage in your ingredients. So we recommend you, the ratio of concentrate to roughage is 6:4. For example, you can use 60% corn, bran, 40% straw, etc. Experiments have shown that this ratio is not only conducive to the formation of particles, but also that animals eat fine and thick, especially sweet, which is conducive to livestock eating.

(4) Questions about additives.

Many friends also asked about additives. Additives are generally not required when pellets are pressed with a feed pellet machine.

Pellets have been semi-cooked during high temperature inhibition, just like people eat them. Cooked food is better than raw food. And in the granulation process, high temperature can kill many bacteria, so no additional additives are needed. Of course, it’s understandable if you want to use it. Written at the end: Different reared animals use different feed ingredients and different diets. When configuring pellet feed ingredients, it can be used flexibly and does not need to follow any principles.

The above are just some of Richi Machinery’s suggestions. In practical application, please pay attention to your actual situation.

1.How can the ring die poultry feed pellet making machine effectively prevent static electricity?

About the operation of the anti-static ring die poultry pellet machine:

(1) Before using the poultry feed pellet machine, it should be checked whether its electrostatic grounding is firm, otherwise wet grinding should not be performed.

(2) Use single grains when grinding wet powder. You need to send a bucket of wet powder from the centrifugal chamber to the grinding chamber, and then transport a bucket of water, so as to avoid concentrated accumulation of particles and avoid the concentration of acetone in the space too high.

(3) On the ring die poultry feed pellet making machine, masks, laundry gloves, anti-static underwear, and anti-static shoes can be worn.

(4) It is forbidden to collide the wet powder hammer and the stainless steel barrel with the silo of the poultry feed pellet making machine to avoid electrostatic sparks.

(5) Before grinding, check the thermometer and hygrometer beside the poultry feed pellet making machine to make sure the humidity is above 50%. If the indoor humidity is lower than 50%, it can be watered and poured before using the poultry feed pellet making machine until the indoor humidity reaches more than 50%. Otherwise, the use of poultry feed pelletizers is not allowed.

2.What is the reason why the new poultry feed pellet making machine does not feed?

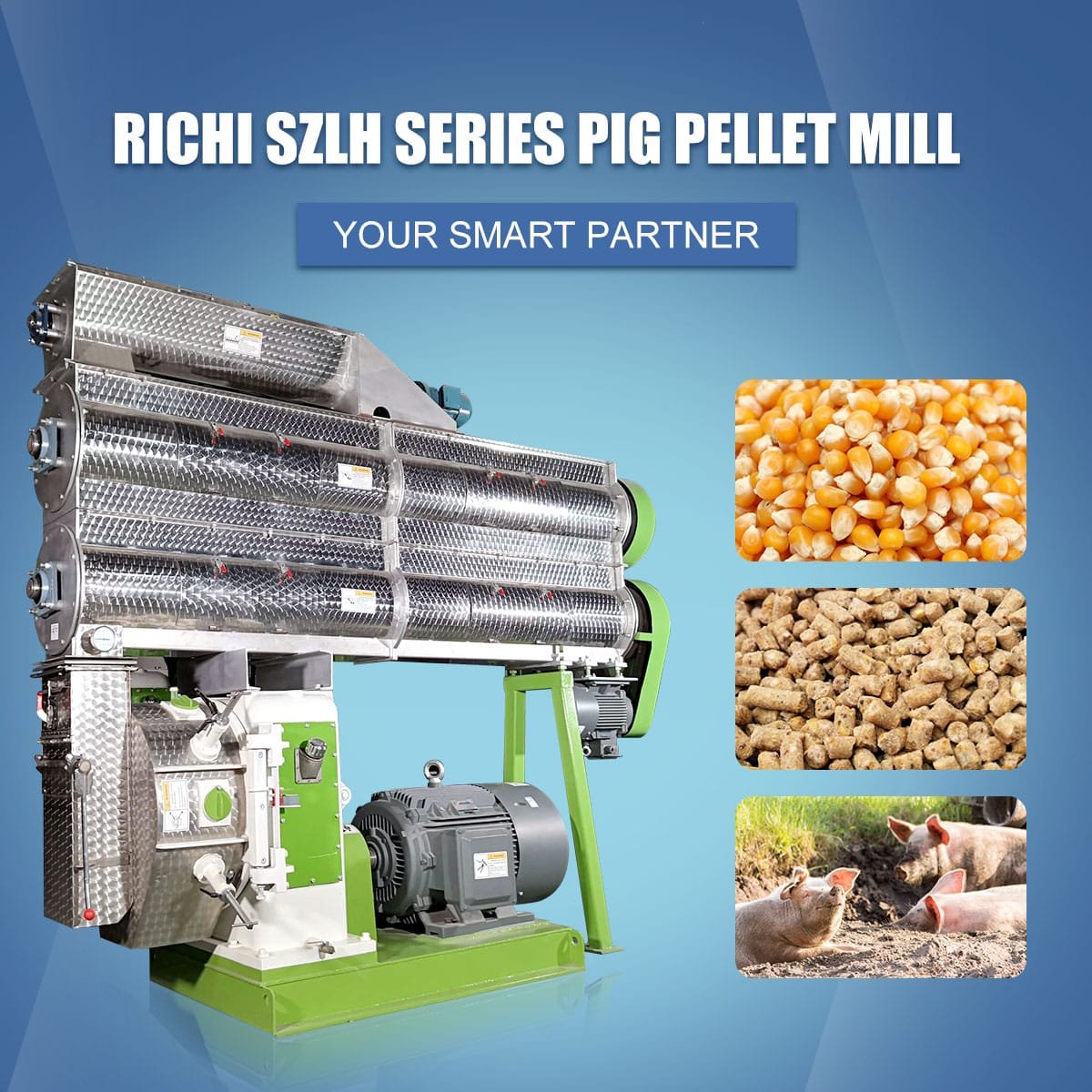

The new poultry feed pellet making machine mainly uses straw raw materials to complete the granulation process. Today, poultry pellet making machines are favored by more and more users, and the number of users investing in new poultry feed machines has also increased.

However, some users’ feed pelletizers are unable to discharge. In fact, the problem that the new poultry pellet feed machine does not feed is not complicated, mainly due to the following reasons:

(1) Mold problem, the newly purchased new machine mold needs to run, so the new pellet needs to run under the raw material with added oil (use 5 kg of feed, 1 kg of feed, 5 kg of fine sand, 2 kg of oil, or no water can be added use waste oil). (Related post: bentonite cat litter production line )

Usually the moisture of the raw material should be controlled between 4-6%. Adjust the gap between the roller and the template to about 1mm. After adjusting the roller, the fixing bolts must be tightened. (If the template hole is blocked, it needs to be opened with a hand drill before adding).

(2) Check the blade and filter. The gap between the knife edge and the filter must be suitable!

(3) The motor of the pellet is reversed. Motors can be dangerous.

(4) Sometimes it can’t be output, and sometimes it can’t be output. Usually, this has nothing to do with forward and reverse rotation of the motor. The length of time is related to the aging degree of the pellet template.

(5) The amount of water also has a great relationship.

(6) The compression ratio of the mold also has a great relationship. (For more: Richi Pellet Machine )