Organic fertilizer pellet machines are essential tools in modern agriculture, transforming raw organic materials into uniform, easy-to-use pellets. The price of these machines can vary widely based on several factors, including the machine’s capacity, features, and the manufacturer. This article explores the price range of organic fertilizer pellet machines and the factors that influence their cost.

Price Range Overview

The price of organic fertilizer pellet mills generally falls within a broad range, from as low as $10,000 to as high as $100,000 or more. Here are some specific examples:

- RICHI Machinery: RICHI offers a variety of organic fertilizer pellet machines with prices ranging from $10,000 to $100,000, depending on the model and capacity.

- Small-Scale Machines: For smaller operations or farms, machines with lower capacities (e.g., 1-2 tons per hour) tend to be on the lower end of the price spectrum, typically between $10,000 and $30,000.

- Medium to Large-Scale Machines: Machines designed for medium to large-scale production (e.g., 5-10 tons per hour) are priced higher, ranging from $30,000 to $70,000.

- Industrial-Scale Machines: High-capacity machines suitable for industrial-scale operations (e.g., over 10 tons per hour) can cost upwards of $70,000 to $100,000 or more.

Factors Influencing the Price

Several factors influence the price of organic fertilizer pellet machines:

- Production Capacity

The machine’s production capacity is a significant determinant of its price:

- Small-Scale Machines: Designed for lower production volumes, these machines are less expensive but may not be suitable for large-scale operations.

- Medium to Large-Scale Machines: These machines offer higher production capacities and are priced accordingly.

- Industrial-Scale Machines: Capable of handling large volumes, these machines come with a higher price tag due to their advanced features and robust construction.

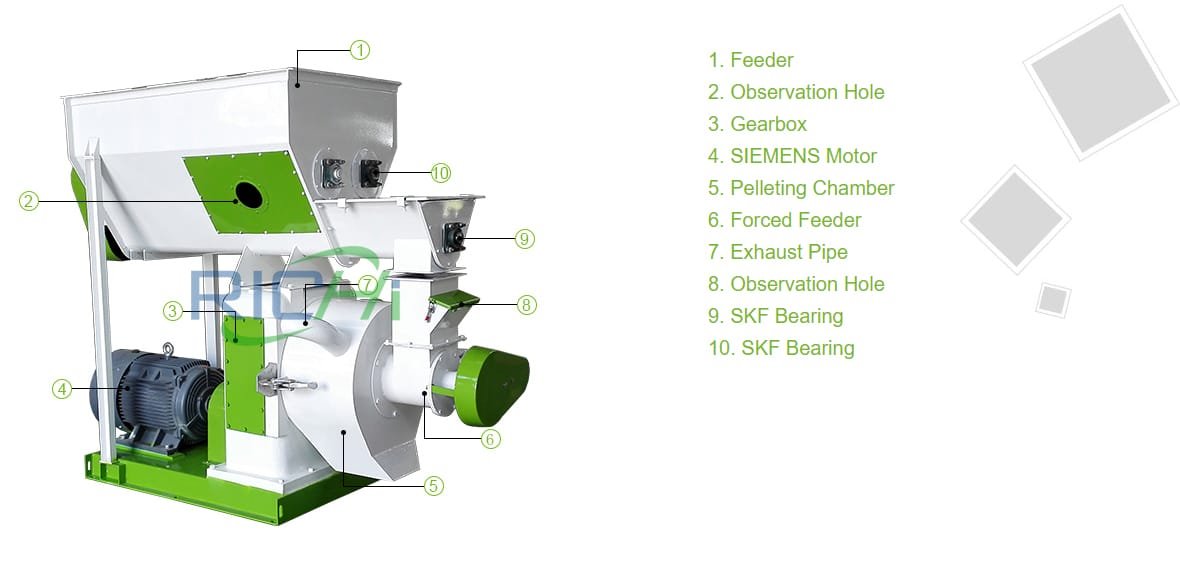

- Machine Features

The specific features and technologies incorporated into the machine also impact its price:

- Basic Models: Machines with basic features and manual controls are generally less expensive.

- Advanced Models: Machines equipped with advanced features such as automated controls, moisture sensors, and temperature regulation systems are priced higher.

- Customization Options: Some manufacturers offer customization options to tailor the machine to specific needs, which can increase the cost.

- Material and Build Quality

The quality of materials and construction affects both the durability and price of the machine:

- Standard Materials: Machines made from standard materials are typically less expensive but may have a shorter lifespan.

- High-Quality Materials: Machines constructed with high-quality, durable materials such as stainless steel or high-grade alloys are more expensive but offer better longevity and performance.

- Brand and Manufacturer

The reputation and expertise of the manufacturer can influence the price:

- Well-Known Brands: Established brands with a reputation for quality and reliability tend to price their machines higher.

- New or Lesser-Known Brands: These manufacturers may offer lower prices to attract customers but may not provide the same level of reliability or after-sales support.

- Geographic Location

The location of the manufacturer and the buyer can also affect the price due to shipping costs and import/export duties:

- Local Manufacturers: Purchasing from local manufacturers can reduce shipping costs and avoid import duties.

- International Manufacturers: Buying from international manufacturers may involve additional costs for shipping and customs clearance.

Examples of Pricing Based on Case Studies

Here are some examples of organic fertilizer pellet machine projects with specific pricing:

- Vietnam: A project using the MZLH320 model with a production capacity of 2,500 tons per year, processing industrial waste, was priced at $80,000.

- Mexico: A project using the MZLH420 model with a production capacity of 10,000 tons per year, processing livestock manure, was priced at $110,000.

- United States: A project using the MZLH858 model with a production capacity of 50,000 tons per year, processing poultry litter, was priced at $430,000.

These examples illustrate how production capacity, raw material type, and geographic location can influence the overall project cost.

Conclusion

The price range of organic fertilizer pellet machines varies widely, from $10,000 to over $100,000, depending on factors such as production capacity, machine features, material and build quality, brand reputation, and geographic location. Understanding these factors can help buyers make informed decisions when selecting a machine that meets their specific needs and budget.

By carefully considering the production requirements, desired features, and available budget, buyers can choose an organic fertilizer pellet machine that offers the best value for their investment. Whether for small-scale farms or large industrial operations, there is a suitable machine available to meet the diverse needs of the organic fertilizer industry.