The process of making fish feed using a fish feed machine typically involves several steps, including ingredient preparation, mixing, grinding, pelleting, and drying. Here is a general overview of the process:

Ingredient preparation: The raw materials for the feed, such as fish meal, soybean meal, corn, and other grains, are prepared and measured according to the desired feed formulation.

Mixing: The raw materials are then mixed together in a mixer to create a homogenous blend of ingredients. The mixer may be a horizontal or vertical type, depending on the machine.

Grinding: The mixture is then ground into a fine powder using a grinder. The grinding process improves the digestibility of the feed and creates a more uniform particle size.

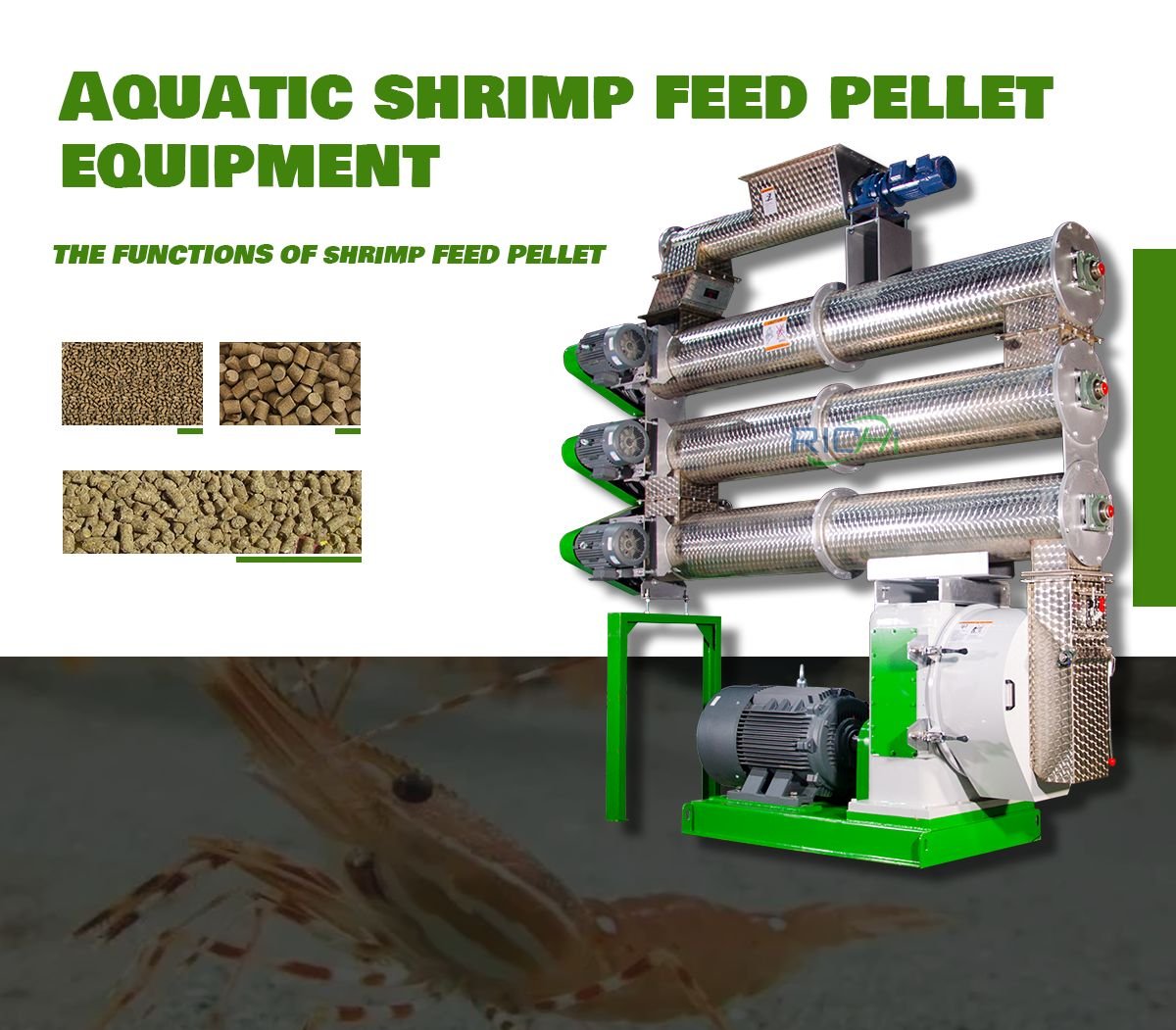

Pelleting: The ground mixture is then fed into the pellet mill, where it is compressed and extruded through a die to form pellets of a specific size and shape. The pellets may be either sinking or floating, depending on the type of fish being fed.

Drying: The pellets are then dried to reduce the moisture content and prevent spoilage. The drying process can be achieved using a dryer or by leaving the pellets in the sun to dry naturally.

Cooling and packaging: After drying, the pellets are cooled and then packaged in bags or containers for storage and transport.

Throughout the process, the fish feed machine regulates and monitors the temperature, pressure, and other parameters to ensure that the feed is of high quality and meets the desired nutritional requirements.

In conclusion, the process of making fish feed using a fish feed machine involves ingredient preparation, mixing, grinding, pelleting, drying, cooling, and packaging. The process is carefully monitored and controlled to ensure that the final product is of high quality and meets the nutritional requirements of the fish being fed.