What is a Wood Pellet Mill?

A wood pellet mill is a sophisticated piece of machinery designed to compress woody biomass into small, dense, cylindrical pellets. These pellets serve as a biofuel, widely recognized for their energy efficiency and eco-friendliness, or as feedstock for the production of various bioproducts. The process involves breaking down raw materials, subjecting them to high pressure and temperature to bind the particles together, and finally shaping them into uniform pellets.

The operation of a wood pellet mill begins with the preparation of the raw materials. This includes woody biomass such as sawdust, wood chips, and agricultural residues. The materials are first screened to remove any contaminants. After this initial step, they go through a grinding process to achieve a consistent particle size, which is essential for the efficient operation of the mill. Once ground, the material is dried to reduce moisture content, enhancing its combustibility and pellet quality.

The next stage is the pelleting process, where the prepared biomass is fed into the pellet mill. Inside, rollers and dies compress the material at high pressure. The wood fibers bond together due to the heat generated from the pressure, producing durable and consistent pellets. These are then cooled and screened to remove fines and ensure uniformity in size.

Wood pellet mills come in two primary configurations: flat die and ring die mills. Flat die mills are generally simpler and are ideal for small-scale operations. They consist of a horizontal roller that presses the biomass through a flat die. On the other hand, ring die mills are more complex and suitable for large-scale production. They use a cylindrical die with a rotating roller that pushes the material through the die holes, offering higher efficiency and pellet quality.

The choice between flat die and ring die mills depends on factors such as production capacity, raw material type, and desired pellet quality. While flat die mills are easier to operate and maintain, ring die mills are favored for their efficiency, durability, and ability to produce high-quality pellets.

The Benefits of Using a Wood Pellet Mill

Utilizing a wood pellet mill offers a multitude of benefits, primarily centered around sustainability and environmental stewardship. One significant advantage is the mill’s ability to convert raw materials, such as sawdust and wood chips, into high-density fuel pellets. This process not only maximizes the utilization of available biomass but also significantly reduces waste, turning by-products of the timber industry into valuable energy resources.

Moreover, wood pellet mills are at the forefront of environmentally-friendly energy solutions. By producing pellets from renewable sources, they help decrease the dependence on fossil fuels, leading to a reduction in greenhouse gas emissions. The combustion of wood pellets is much cleaner compared to coal, oil, or natural gas, contributing to a lower carbon footprint and promoting a healthier environment.

Another profound benefit of wood pellet mills is their cost-effectiveness. For businesses, this translates into lower expenditure on waste management and energy costs. Transforming otherwise discarded wood residues into fuel can create an additional revenue stream and decrease the need for external energy purchases. For consumers, using wood pellets for heating can offer substantial savings over time due to the lower cost of raw materials and greater efficiency of pellet stoves and boilers.

Energy independence is also a pivotal advantage offered by wood pellet mills. By harnessing localized biomass resources, communities can reduce their reliance on imported energy, thus enhancing energy security. This local sourcing enables a steady and reliable supply, shielded from international market fluctuations.

Economically, the pellet mill industry can also stimulate job creation and regional development. As demand for biomass energy grows, so too does the need for skilled labor in the production and supply chain, providing new opportunities and fostering local economies.

Overall, the benefits of using a wood pellet mill are wide-ranging, making it an ideal solution for sustainable energy generation, cost reduction, and economic growth. These advantages highlight the critical role of wood pellet mills in the transition to a more resilient and eco-friendly energy landscape.

Why Choose a Wood Pellet Mill?

In today’s rapidly evolving energy landscape, investing in a wood pellet mill offers significant advantages for individuals and businesses alike. One of the primary reasons for choosing a wood pellet mill is its flexibility and versatility in handling various types of feedstock. From wood chips and sawdust to agricultural residues, a modern wood pellet mill can process an array of raw materials, making it a robust solution for different production needs. This adaptability ensures that the source material is transformed into high-quality pellets, suitable for diverse applications from heating systems to industrial boilers.

Moreover, a wood pellet mill allows producers to generate pellets that meet stringent quality standards. Advanced machinery ensures the consistency of pellet size, density, and moisture levels, crucial for efficient combustion and optimal energy output. By producing a superior product, businesses can meet market demands more effectively and gain a competitive edge.

Another compelling reason for investing in a wood pellet mill is the overall improvement in energy production efficiency. Pellets are a highly efficient fuel source, offering a high energy-to-weight ratio compared to other biomass fuels. This efficiency translates into lower operational costs and maximized energy yields, benefiting both producers and end-users. Furthermore, the simplicity of pellet storage and transportation adds another layer of operational efficiency, making these mills an integral part of sustainable energy practices.

The potential for revenue generation through the sale of wood pellets cannot be overlooked. As the demand for renewable energy sources surges globally, wood pellets are emerging as a favored option. This growing market offers abundant opportunities for profit, especially with policies and incentives increasingly supporting renewable energy investments. For businesses aiming to diversify their revenue streams or capitalize on sustainable practices, a wood pellet mill is a worthwhile investment.

All these factors contribute to a compelling case for choosing a wood pellet mill. The combination of versatility, quality assurance, enhanced efficiency, and revenue potential firmly establishes wood pellet mills as essential assets in the move towards greener energy solutions.

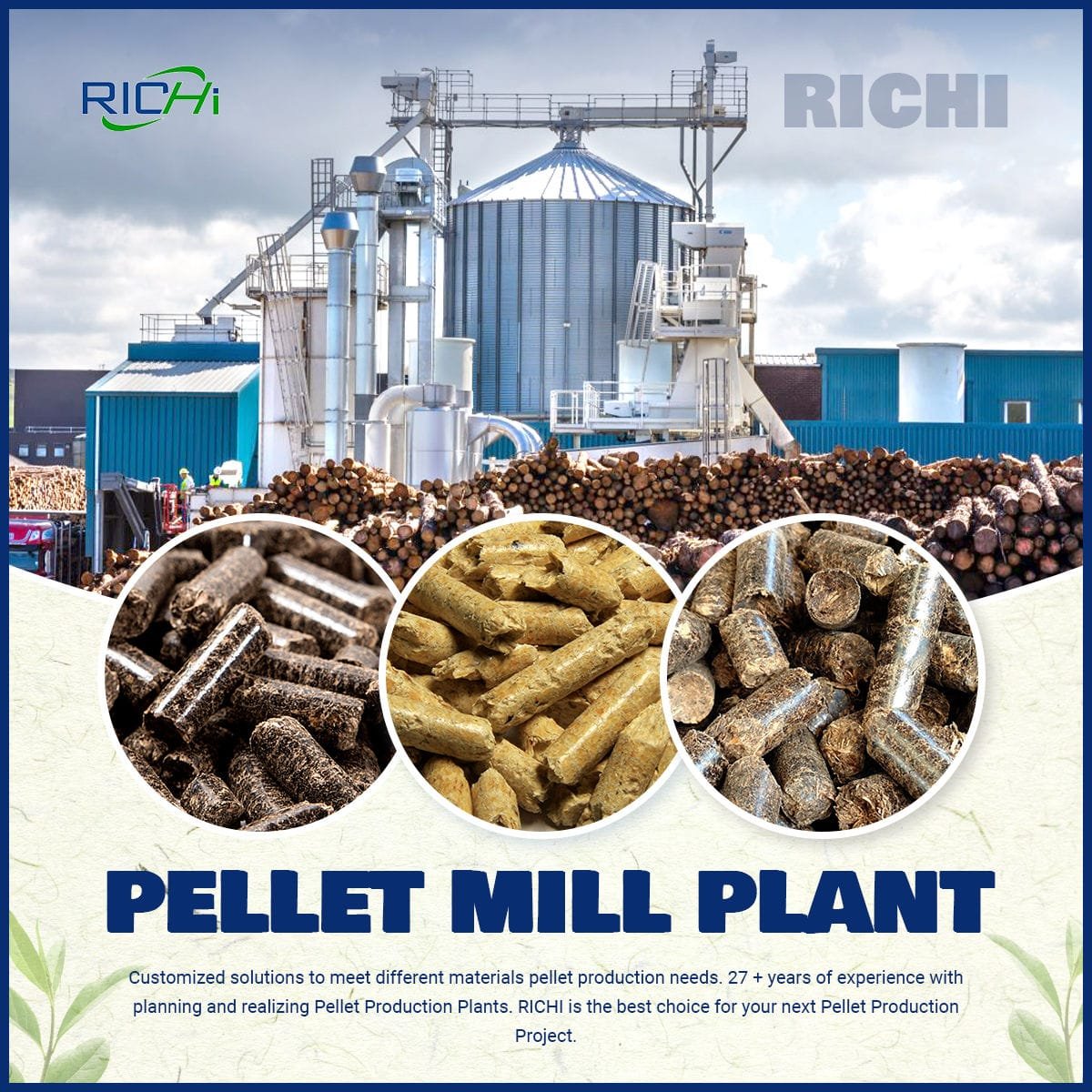

Why Should I Choose Richi Machinery as a Supplier?

Richi Machinery has established itself as a frontrunner in the wood pellet mill industry through a robust blend of expertise, innovative technology, and unwavering commitment to customer satisfaction. With decades of experience, Richi Machinery has cultivated a formidable reputation for delivering high-quality and durable wood pellet mills that meet a broad range of industry needs. Their dedication to excellence is evident in every machine they produce, ensuring consistent performance and longevity.

One of the core strengths of Richi Machinery lies in their advanced technology and innovative features. Each wood pellet mill is designed with state-of-the-art engineering to maximize efficiency and productivity. The incorporation of cutting-edge features such as automatic lubrication systems and digital control panels ensures seamless operation and minimal downtime. This commitment to technological innovation not only enhances the performance of their machines but also provides users with a competitive edge in the market.

Customer satisfaction is paramount to Richi Machinery. This is reflected in their comprehensive after-sales service, which includes extensive warranties and dedicated customer support. Richi’s support team is readily available to address any issues, ensuring that clients receive timely and effective solutions. Moreover, the company offers thorough training and maintenance tips to help customers optimize the use of their wood pellet mills.

Testimonials and case studies from satisfied customers further attest to Richi Machinery’s credibility and reliability. Numerous clients have reported significant improvements in their operational efficiency and product quality, thanks to the robust and user-friendly design of Richi’s wood pellet mills. These positive experiences reinforce the trust and confidence that the market places in Richi as a trusted supplier.

In sum, choosing Richi Machinery as a supplier of wood pellet mills means partnering with a company that values quality, innovation, and customer satisfaction. Their holistic approach to product development and customer care ensures that clients not only receive top-tier equipment but also unparalleled support throughout the product’s lifecycle.

Case: Wood Pellet Plant in Romania with 2-2.5T/H by RICHI