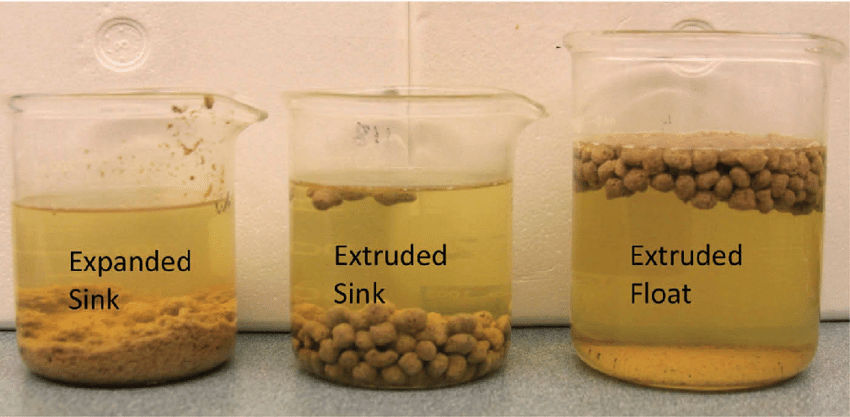

Extrusion is the cooking of the active ingredient combination in an extruder via temperature level, humidity and also pressure. Moisture gives lubrication for compression and also extrusion and also creates some pasting of the raw starch on the active ingredient surface area at heats, causing bond.

Within 20 seconds of getting in puffing, the ingredients alter from an air-dried (about 10-12% dampness) state at ambient temperature level to 15-16% moisture at 80-90 ° C. Throughout the subsequent compression and extrusion of the holes in the die, rubbing elevates the feed temperature level to virtually 92 ° C.

Extrusion is a process in which the food is not only compressed like pellets, yet also “prepared”, that is why it requires higher dampness, higher temperature and also greater stress than pellets.

When it leaves the extruder, all these requirements should be fulfilled to accomplish the preferred degree of development.

In addition, as mentioned over, the various other benefits of extruded feed consist of reduced contamination, longer stability in water and maintaining all its nutrients, higher digestibility, high effectiveness and also high conversion price. Thus, extruded feed is a greater qualified feed which can improve the profitability of fish farms.