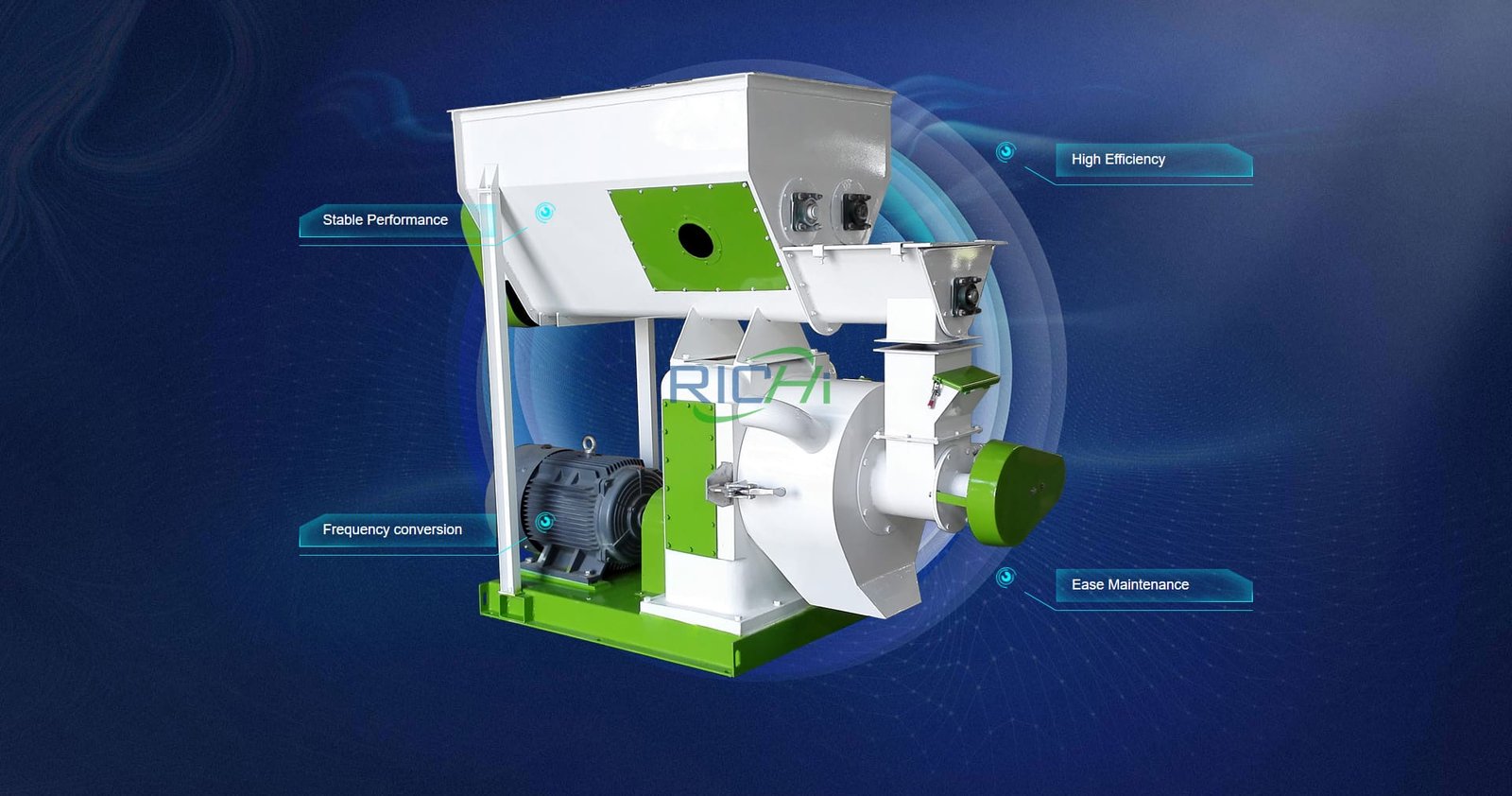

In the landscape of sustainable agriculture and waste management, poultry manure has evolved from a byproduct into a valuable organic fertilizer and soil amendment. Central to harnessing its potential is the poultry manure pellet machine – a specialized equipment designed to transform raw poultry manure into dense, uniform pellets for easier handling, storage, and application.

Importance of Preventive Maintenance

Preventive maintenance forms the foundation of a reliable equipment maintenance program. By proactively addressing potential issues before they escalate, preventive maintenance minimizes downtime, reduces repair costs, and extends the lifespan of poultry manure pellet machines. This approach includes regular inspections, cleaning, lubrication, and timely component replacements according to manufacturer recommendations and industry standards.

Related post: https://www.richipelletmachine.com/chicken-manure-pellet-machine/

Developing a Comprehensive Maintenance Plan

To effectively maintain poultry manure pellet machines, develop a tailored maintenance plan that encompasses:

- Routine Inspections and Cleaning: Regularly inspect critical components such as pellet mills, die assemblies, bearings, motors, and material handling systems. Implement thorough cleaning procedures to remove debris and contaminants.

- Lubrication and Component Replacements: Follow manufacturer guidelines for proper lubrication schedules and types. Replace wear-prone components like bearings and seals as per manufacturer specifications or based on inspection findings.

- Monitoring and Troubleshooting: Implement monitoring systems to track performance indicators such as production rates and temperature levels. Promptly troubleshoot deviations from normal operating parameters to prevent equipment failures.

- Safety Considerations: Prioritize safety with comprehensive protocols addressing hazards such as moving parts and high temperatures. Ensure personnel are trained in safety procedures and equipped with appropriate PPE. Regularly inspect and maintain safety devices.

- Training and Documentation: Invest in training programs covering machine operation, troubleshooting, and safety protocols for maintenance personnel. Maintain detailed documentation of maintenance activities, repairs, and safety inspections to support consistent practices and training efforts.

Partnering with Experts and Manufacturers

Leverage the expertise of technicians, consultants, and manufacturer support teams to stay abreast of best practices and technological advancements in poultry manure pellet machine maintenance. Attend industry events and training sessions to remain informed about emerging trends and sustainable waste management practices.

Conclusion

By prioritizing preventive maintenance, developing a comprehensive maintenance plan, and adhering to best practices for inspections, cleaning, lubrication, and component replacements, you can ensure optimal performance, longevity, and safety of poultry manure pellet machines. This proactive approach not only enhances operational efficiency and reduces costs but also contributes to sustainable agriculture and environmental stewardship goals.