What Is Dry Type Fish Feed Extruder?

There are two sorts of fish feed devices for making floating marine feed, one is dry type fish feed extruder, the various other is wet type fish feed extruder.

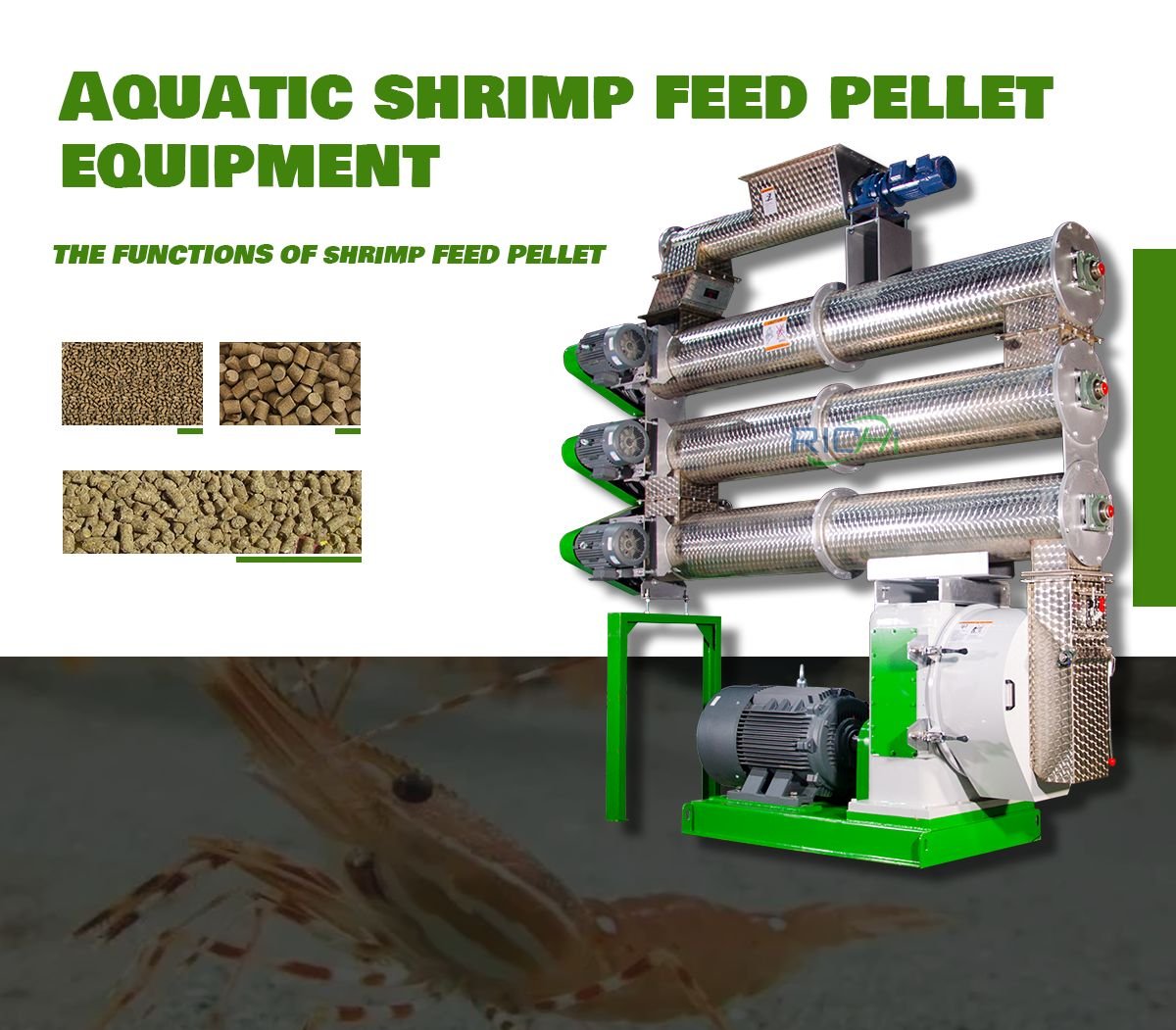

The dry type fish feed extruder is mainly utilized for the production of aquatic feed, such as making fish feed pellets, tilapia feed, catfish feed pellets, shrimp feed, crab feed, turtle feed, fish feed pellets, etc. The ended up pellet feed is extruded at heat with the heating plate in the completely dry type fish feed maker.

Consequently, the completed granules can float on the water for concerning 24 hours because of being puffed. Completed particle dimensions can be 0.9 mm, 1mm, 1.5 mm, 2mm, 2.5 mm, 3mm, 3.5 mm, 4mm, 4.5 mm, 5mm, 5.5 mm, 6mm etc approximately a larger 15mm. dry type device heating the product by electric heating plate, this dry type machnine squeezes out the product from the holes of the die under the activity of the screw extruder.

When the pellets appear of the device, the pressure and also temperature drop dramatically, and the water vaporizes. The product is then increased right into bits with a permeable structure. Throughout this procedure, wetness ranges from 15% to 20%.

Functioning Concept Of Dry Type Fish Feed Extruder

when extrusion procedure, the material from the open end of the extrusion tooth cavity input, by the screw transportation to the whole extrusion tooth cavity, and afterwards the supporting extrusion component into a number of locations, in each location between the positioning of a ring (pressure ring) as the circulation and also pressure control, the screw communicating activity to promote the material circulation through the ring void between the stress ring and also the within the dental caries, the mechanical energy produced by the rotational activity of the screw right into warm The rubbing between the product and the parts of the dry type fish feed extruder maker as well as the interior friction of the material.

As the product is squeezed out through the die hole at the end of the puffing dental caries, the dough-like product is processed right into a particular form, and also due to the big propulsion of the screw in the blowing tooth cavity of the dry type fish feed device, a massive pressure is produced.

Developing in the material, when these materials are extruded from the die hole, a huge quantity of water in the material vaporizes instantly, which substantially decreases the moisture material of the product.

What Is Wet Type Fish Feed Extruder?

Wet type fish feed extruder maker is also widely used to generate resources right into high-grade floating water feed pellets, which appropriates for fish, catfish, shrimp, crab, feline, pet and other pets. The raw materials used by the wet type fish feed maker are wheat, soybean, cake as well as various other scraps, etc, and the puffed fragments created by the wet type fish feed extruder equipment can drift on the water surface for greater than 24 hours without liquifying.

Wet type feed extruder equipment are mostly made use of in huge as well as medium-sized feed handling plants as well as ranches. it deals with the steam central heating boiler, the boiler continually can provide hot vapor to the wet type fish feed maker extrusion component.

The functioning principle of the wet type equipment is similar to that of the dry type fish feed extruder machine. However the damp type calls for adding water or heavy steam in the damp type fish feed maker to boost the dampness to twenty percent, or more than thirty percent during processing. It raises the temperature of the product by vapor.

Working Concept Of Wet Type Fish Feed Extruder

the wet type fish feed device includes screw, barrel, design template, fixture, etc. The screw and also barrel are incorporated in areas, and also the compression level can be changed according to the type and also demands of the extruded feed, and also the development level of the extruded feed can be changed.

When the raw product goes into the loading device, no extra home heating is needed and the screw is pressurized at high pressure and also high temperature to completely prepare and sterilize the raw material.

During the heat healing procedure, the starch and also fibers in the raw material expand. The material is after that molded into pellets via the molding die under pressure-sealed problems.

Finally, the high pressure produced by the regular rotation of the screw is reduced by the normal high-speed turning of the front cutter, and also the completed product is reduced right into an average little puffed round at area temperature and also pressure.