In the ever-evolving landscape of sustainable agriculture and waste management, the utilization of organic manures has emerged as a powerful solution for promoting soil health, enhancing crop yields, and reducing reliance on synthetic fertilizers. However, handling and processing raw organic materials can be a labor-intensive and logistically challenging task. Enter the organic manure making machine – a specialized piece of equipment designed to streamline the production of high-quality organic manures, transforming various organic waste streams into valuable soil amendments.

These innovative machines are engineered to incorporate cutting-edge technologies and features that not only enhance efficiency and productivity but also prioritize environmental sustainability and user-friendliness. In this article, we’ll explore the remarkable features of organic manure making machines, highlighting their capabilities and the benefits they offer to farmers, gardeners, and environmentally conscious individuals.

Robust and Versatile Material Handling Capabilities

One of the standout features of organic manure making machines is their ability to process a wide range of organic materials, including animal manures, crop residues, food waste, and municipal green waste. These machines are equipped with robust material handling systems, such as conveyors, hoppers, and shredders, designed to efficiently handle and pre-process various feedstocks.

Additionally, many organic manure making machines incorporate advanced mixing and blending mechanisms, allowing users to create customized organic manure formulations tailored to their specific soil and crop requirements. This versatility ensures that the final product meets the desired nutrient profile and physical characteristics, optimizing its effectiveness as a soil amendment.

Efficient Composting and Stabilization Processes

At the core of organic manure making machines lies their ability to facilitate efficient composting and stabilization processes. These machines often incorporate advanced aeration and temperature control systems, ensuring optimal conditions for microbial activity and decomposition of organic matter.

Some machines even feature integrated turning and mixing mechanisms, which help to aerate the composting material and promote uniform decomposition. This not only accelerates the composting process but also helps to reduce odors and potential pathogen levels, resulting in a safer and more pleasant working environment.

Related post: https://www.richipelletmachine.com/bio-fertilizer-plant-project-cost/

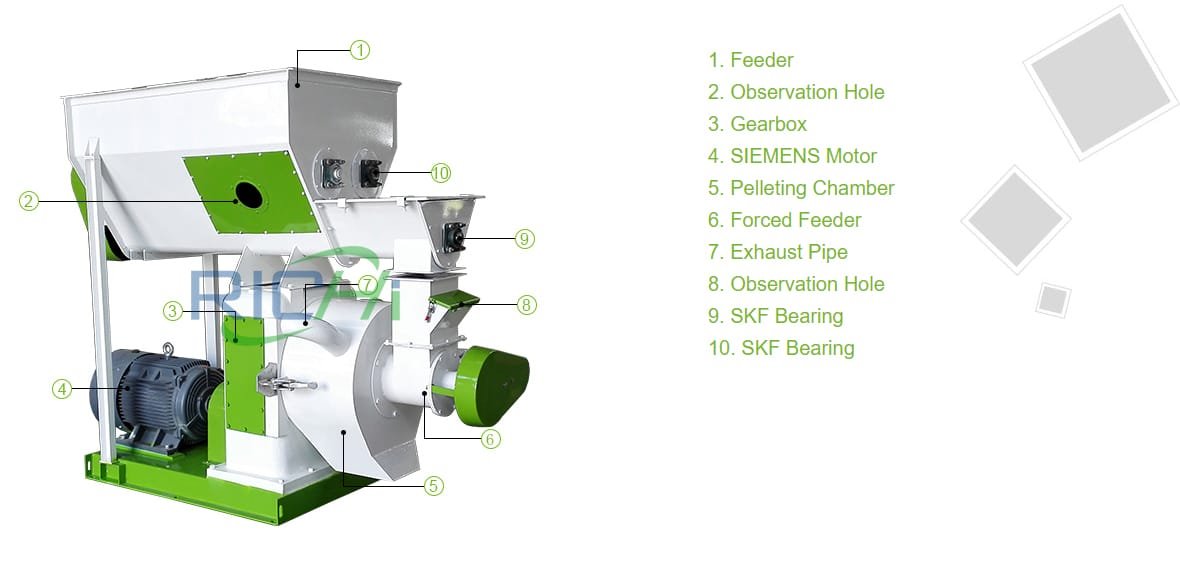

Advanced Drying and Pelletizing Technologies

To enhance the handling, storage, and application of organic manures, many organic manure making machines incorporate advanced drying and pelletizing technologies. These features allow for the production of dense, uniform pellets or granules, which offer numerous advantages over loose, unprocessed organic materials.

Pelletized or granulated organic manures are easier to handle, transport, and apply using conventional fertilizer spreaders or broadcasters. Additionally, the pelletizing process can improve nutrient availability and extend the nutrient release profile, ensuring a consistent supply of nutrients to plants throughout the growing season.

Energy-Efficient and Sustainable Design

In line with the principles of sustainable agriculture and environmental stewardship, organic manure making machines are designed with energy efficiency and sustainability in mind.

Many manufacturers incorporate energy-saving technologies, such as variable frequency drives, regenerative braking systems, and waste heat recovery units, to minimize energy consumption and reduce operational costs.Furthermore, some machines are designed to integrate with renewable energy sources, such as solar panels or biogas generators, further reducing their environmental impact and promoting sustainable practices.

This alignment with sustainable design principles not only contributes to the reduction of greenhouse gas emissions and environmental pollution but also positions organic manure producers as leaders in the growing market for eco-friendly and socially responsible products.

User-Friendly Controls and Automation Features

Modern organic manure making machines are designed with user-friendly controls and automation features, making them accessible and easy to operate for a wide range of users. These machines often feature intuitive control panels or touchscreen interfaces that allow operators to monitor and adjust various parameters, such as temperature, moisture levels, and processing times.

Additionally, many machines incorporate advanced automation systems that can automatically adjust and optimize the production process based on real-time data and feedback, ensuring consistent product quality and maximizing production efficiency. These user-friendly controls and automation features not only simplify the operation of the machines but also contribute to increased productivity, reduced downtime, and improved safety for operators.

Modular and Scalable Designs

To cater to the diverse needs of various users, from small-scale farmers and gardeners to large-scale commercial operations, organic manure making machines are often designed with modularity and scalability in mind. These machines can be configured with different components and processing modules, allowing users to customize the system to their specific requirements and production capacities.

As business needs evolve or production demands increase, the modular design of these machines enables seamless expansion or upgrades, minimizing the need for costly equipment replacements. This scalability ensures that users can adapt to changing market conditions and growth opportunities, future-proofing their investment in organic manure production technology.

Comprehensive Quality Control and Monitoring Systems

Ensuring the consistent quality and safety of organic manures is paramount for maintaining consumer trust and regulatory compliance. To address this critical aspect, organic manure making machines often incorporate comprehensive quality control and monitoring systems.These systems may include advanced sensors and probes for monitoring temperature, moisture levels, and other critical parameters during the composting and processing stages.

Additionally, many machines feature integrated sampling and testing capabilities, allowing for real-time analysis of the organic manure’s nutrient content, pH levels, and potential contaminants.By implementing robust quality control and monitoring systems, organic manure producers can ensure that their products meet the highest standards of quality and safety, while also adhering to relevant industry regulations and certifications.

As the world continues to embrace sustainable practices and circular economy principles, the demand for organic manures and soil amendments is expected to rise, presenting lucrative opportunities for businesses and individuals in this sector. By investing in organic manure making machines equipped with these innovative features, producers can not only capitalize on this growing market but also contribute to the growth of sustainable agriculture, promote soil health, and support the transition towards a more environmentally responsible future.

For details please contact: pellet mill machine

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com