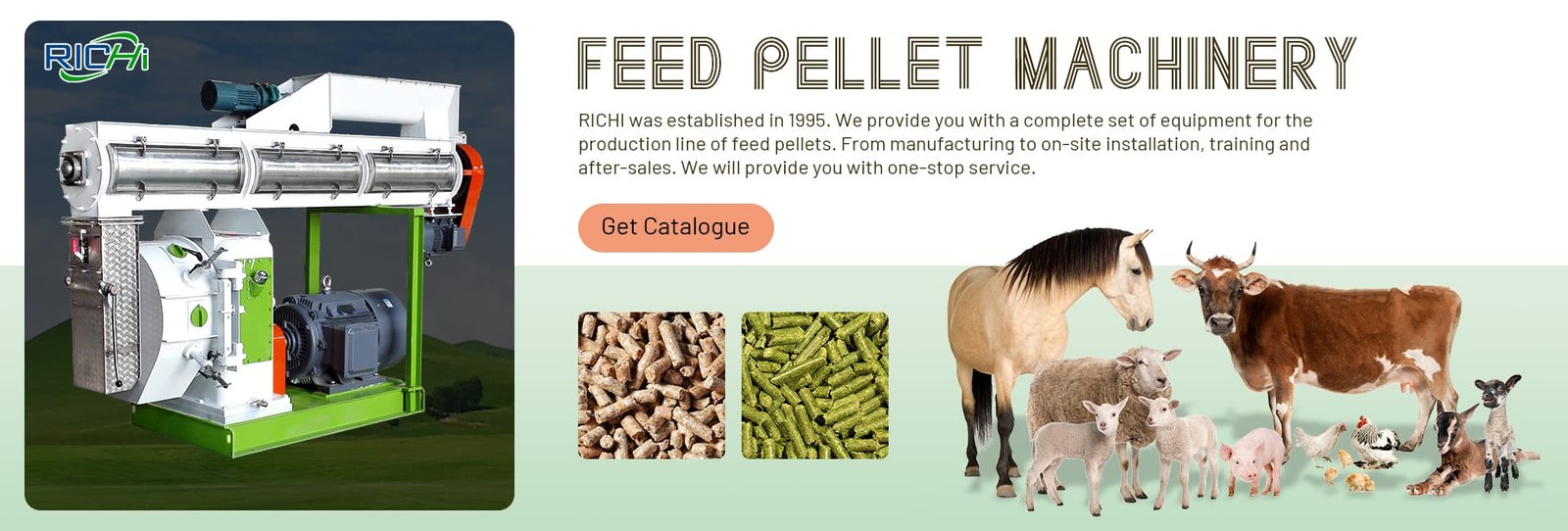

In the dynamic world of animal farming and livestock production, ensuring a consistent supply of high-quality and nutritionally balanced feed is paramount for maintaining the health, growth, and productivity of animals. Feed mill pellet machines have emerged as essential equipment, offering a comprehensive solution for efficient and sustainable feed production. These specialized machines transform loose feed ingredients into dense, cylindrical pellets, providing numerous advantages over traditional feed forms, including improved handling, storage, transportation, and consistent nutrient delivery.

Operating a feed mill pellet machine requires a thorough understanding of its working principles, proper setup, and maintenance procedures. By following best practices and adhering to safety protocols, operators can maximize the machine’s performance, ensure consistent pellet quality, and contribute to the overall success of their animal farming operations.

Preparing for Operation

Before operating an animal feed pellet machine, it is crucial to ensure that all necessary preparations have been made. This includes:

Raw Material Preparation: Ensure that the raw materials, such as grains, oilseeds, protein sources, and various additives, are properly prepared and meet the required specifications for particle size, moisture content, and homogeneity. Different feedstocks may require specific pre-treatment processes, such as drying, grinding, or size reduction.

Machine Setup and Calibration: Carefully review the manufacturer’s instructions and set up the pellet machine according to the recommended specifications. Calibrate the machine’s parameters, such as temperature, pressure, and feed rates, based on the type of feedstock and desired pellet characteristics.

Safety Checks: Conduct a thorough safety inspection of the machine, ensuring that all guards, safety devices, and emergency stop mechanisms are in proper working condition. Verify that the machine is properly grounded and that all electrical connections are secure.

Personal Protective Equipment (PPE): Ensure that all operators and personnel involved in the pelleting process are equipped with appropriate PPE, such as safety glasses, hard hats, steel-toed boots, and hearing protection, as required by the manufacturer and local regulations.

Related post: https://www.pellet-richi.com/feed-pellet-machine/goat-feed-pellet-making-machine.html

Step-by-Step Operation

Once the necessary preparations have been made, follow these steps to operate the feed mill pellet machine:

Feeder System Operation: Load the prepared feedstock into the feeder system, ensuring a consistent and controlled flow of material into the pellet machine. Adjust the feeder settings as per the manufacturer’s recommendations to maintain the desired feed rate.

Conditioning and Binding: If necessary, introduce conditioning agents or binders to the feedstock to improve pellet durability and strength. Adjust moisture levels as required for optimal pelleting, typically within the range of 10-18% moisture content.

Pelleting Operation: Engage the pelleting unit and monitor the process closely. Adjust parameters such as temperature, pressure, and feed rates as needed to achieve the desired pellet size, density, and quality. Ensure that the cooling and drying systems are functioning properly to stabilize the freshly formed pellets.

Quality Control and Monitoring: Regularly monitor the pellet quality, including size, density, moisture content, and durability. Adjust process parameters as needed to maintain consistent pellet quality and address any deviations from the desired specifications.

Pellet Collection and Packaging: Collect the finished pellets and package them appropriately for storage, transportation, or direct use. Proper packaging helps maintain pellet quality and prevents moisture absorption or contamination.

Maintenance and Cleaning: Perform regular maintenance and cleaning of the pellet machine to ensure optimal performance and longevity. Follow the manufacturer’s recommendations for maintenance schedules and procedures, including lubrication, component inspections, and replacements as needed.

Optimizing Pellet Quality and Efficiency

To achieve optimal pellet quality and production efficiency, consider the following factors and best practices:

Feedstock Quality: The quality and composition of the feedstock play a crucial role in determining the pellet quality and production efficiency. Ensure consistent feedstock quality by implementing strict quality control measures and maintaining reliable supply chains.

Die Specifications: The design and specifications of the pellet die, including the number and size of holes, as well as the die material, can significantly impact pellet quality, production rates, and energy consumption. Select the appropriate die based on your specific requirements and feedstock characteristics.

Temperature and Pressure Control: Maintaining optimal temperature and pressure levels during the pelleting process is essential for achieving the desired pellet density, durability, and nutrient availability. Regularly monitor and adjust these parameters based on the feedstock and desired pellet specifications.

Conditioning and Binding Agents: Proper conditioning and the use of appropriate binding agents can improve pellet durability, reduce fines (small pellet fragments), and enhance overall pellet quality. Experiment with different conditioning techniques and binding agents to find the optimal combination for your specific feedstock.

Maintenance and Wear Management: Regular maintenance and timely replacement of worn components, such as the pellet die and rollers, are crucial for maintaining consistent pellet quality and production efficiency over time. Implement a preventive maintenance program to minimize downtime and extend the lifespan of the machine.

Operator Training and Expertise: Invest in comprehensive training programs for operators to ensure they have a thorough understanding of the machine’s operation, troubleshooting techniques, and safety protocols. Experienced and knowledgeable operators can significantly contribute to optimizing the pelleting process and maximizing productivity.

Continuous Improvement: Adopt a culture of continuous improvement by regularly evaluating and optimizing processes, exploring opportunities for process upgrades or technology advancements, and staying up-to-date with industry best practices and innovations.

Safety Considerations

Safety should always be a top priority when operating a feed mill pellet machine. Adhere to the following safety guidelines:

Lockout/Tagout Procedures: Implement and strictly follow lockout/tagout procedures when performing maintenance, cleaning, or any other tasks that require accessing the machine’s internal components. This ensures that the machine is properly isolated from all energy sources, preventing accidental start-ups or releases of stored energy.

Guarding and Safety Devices: Ensure that all guards, safety devices, and emergency stop mechanisms are in place and functioning correctly. Never bypass or disable these safety features, as they are designed to protect operators and personnel from potential hazards.

Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, hard hats, steel-toed boots, and hearing protection, when operating or working around the pellet machine. Consult the manufacturer’s recommendations and local regulations for specific PPE requirements.

Housekeeping and Cleanliness: Maintain a clean and organized work area around the pellet machine. Remove any potential trip hazards, and ensure that walkways and access points are clear of obstructions. Proper housekeeping can help prevent accidents and facilitate safe operation.

Training and Awareness: Ensure that all operators and personnel involved in the pelleting process receive comprehensive training on the safe operation of the machine, emergency procedures, and hazard identification and mitigation. Regular safety briefings and awareness campaigns can reinforce safe practices and promote a culture of safety within the workplace.

By following these guidelines and adhering to best practices, operators can effectively operate feed mill pellet machines, ensuring consistent pellet quality, maximizing production efficiency, and promoting a safe and sustainable animal farming operation.